Essential Guide to Conformal Coating Types & Applications

Electronics are all around us. Consumer electronics take the form of TVs, smartphones, refrigerators, and washing machines. Electronics also have specialized applications in sectors such as automotive, aerospace, and medicine. A key component of most electronics is a printed circuit board (PCB).

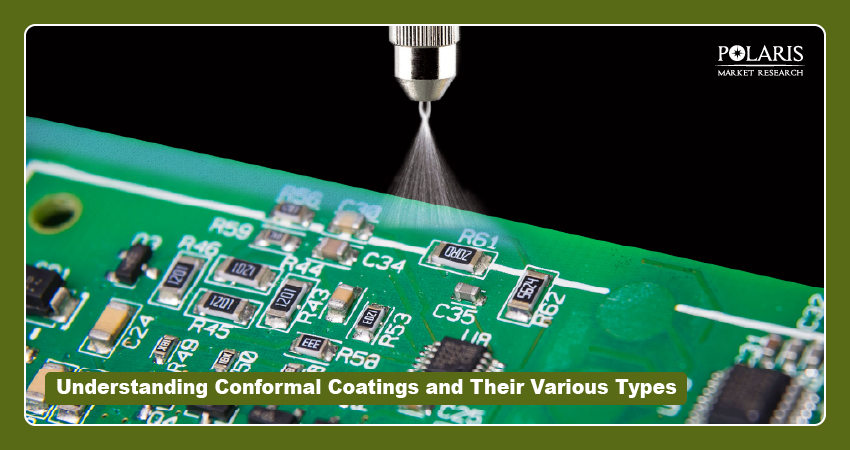

When manufacturing PCBs, they need to be protected from adverse environmental conditions. Several treatments and coatings are used for the same. In this blog post, we explain to you the essentials of conformal coatings. We cover their types and their application process. The key metrics for the conformal coatings market have also been detailed. Stick with us!

Conformal Coatings: Introduction

A conformal coating is a thin protective film. It is applied to a PCB to protect it against corrosion and other environmental conditions. The application of the film is typically done at 25-250µm. It conforms to the shape of the board and its components. Conformal coatings cover and protect solder joints, exposed traces, and the leads of electronic components. Other metallized areas of the board are also protected from corrosion. Using PCB, the working life of the PCB gets extended.

Conformal Coatings Market Metrics

We’ve done a detailed analysis of the conformal coatings market. Our assessment reveals that the market for these coatings stood at USD 1.01 billion in 2024. The market is projected to exhibit a CAGR of 6.1% from 2025 to 2034.

Types of Conformal Coatings

The categorization of conformal coatings is done based on their base chemistry. Each option has its own beneficial properties for the different operating environments of the PCB. Below is an explanation of some of the most widely used conformal coating types:

Acrylic-Based Coatings

These coatings combine an affordable price with ease of application. They also offer good environmental protection. Acrylic-based coatings retain their clarity and can resist hydrolysis when they are exposed to exterior environments for extended periods. However, the solvent resistance of these coatings is limited. As such, they are suitable for rework but aren’t the preferred choice for applications that need chemical resistance.

The operating temperature range of acrylic coatings is wide. Their application and removal are also easy. Additionally, acrylic-based coatings can be dried quickly at room temperature with the use of simple solvent evaporation. Acrylic coatings can adhere to a wide range of substrates.

Silicone-Based Coatings

Silicone coatings are capable of retaining elasticity after curing. So, they offer good protection against the effects of mechanical stress and vibrations on boards. Silicone products, as explored in the silicone market report, are capable of providing good resistance against moisture and corrosion. The resistance to chemical contamination of these coatings is also good.

Silicone coatings offer a wide range of protection. They are suitable for both rapidly changing and challenging environments. These coatings can easily manage temperatures up to 200 degrees Celsius. The higher thermal resistance of silicone-based coatings means they can block the dissipation of heat.

Polyurethane-Based Coatings

Polyurethane is known for its high toughness and adhesion. Also, it offers strong resistance against solvents and other chemical contaminants. So, the use of polyurethane coatings protects circuit boards that are exposed to harsh environments. These coatings have also been approved for use in medical devices by the U.S. FDA.

The curing process for polyurethane-based coatings requires the use of an oven for controlled heating. The controlled heating needs to be done for extended periods. Alternatively, the material can be exposed to UV light. As such, the curing process is more suitable for commercial production instead of low-volume prototyping.

Epoxy-Based Coatings

Epoxy-based coatings provide a smooth and tough finish. The finish of these coatings can resist chips and cracks. So, good protection is provided against moisture ingress and abrasion. Another key benefit of the solutions from the epoxy coatings market is that they protect against chemical contamination. This makes them suitable for harsh industrial environments.

A downside of these coatings is that preparing and applying the epoxy material is complex. Additionally, the curing of epoxy material into a tough coating means the desired flexibility won’t be obtained if the movement or flexing of the board takes place.

Application Methods for Conformal Coatings

Manual Spraying: This method is usually used in low-volume production. It is because capital equipment isn’t typically available. The application of the coating here is done with the use of a hand-held spray gun or aerosol can. Manual spraying consumes a significant amount of time and may require masking. Also, the consistency and quality of the coating here is largely based on the operator. So, variations from board to board may be there.

Automated Spraying: Automated spraying involves the use of programmed spray systems. Here, a conveyor is used for moving the PCBs. A reciprocating spray head coats the PCB as it moves on the conveyor.

Selective Coating: Automated spray systems can be programmed to apply the conformal coating to specific areas of the board. A robotic spray nozzle can be used for the same. Selective coating is widely used for high-volume assembly, as it takes away the need for the labor-intensive masking process.

AI and the Conformal Coatings Market

Artificial intelligence (AI) is capable of analyzing chemical formulations and curing times. This helps in the development of conformal coatings with improved performance. The predictive modeling capabilities of AI help lower the cost of experiments and improve the speed of innovation cycles. Insights into market demands and preferences of customers by AI-powered analytics help the creation of more effective products.

Conclusion

The application of conformal coatings is a key aspect of PCB manufacturing. These coatings provide protection against the operating environment. Its use also reduces failure rates and increases its working life. There are various coating types available in the conformal coatings market. The selection of a particular coating requires balancing the properties of each coating type with the specific application requirements.