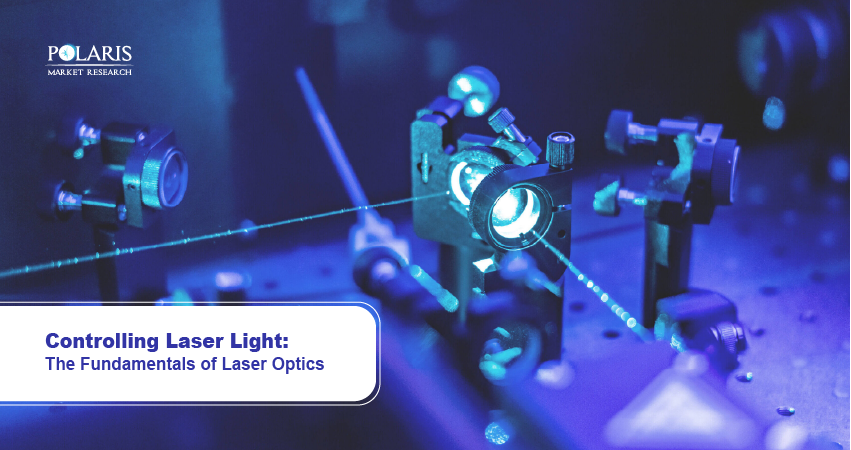

Controlling Laser Light: The Fundamentals of Laser Optics

Lasers have become ubiquitous in the modern world. From powering high-speed internet to driving autonomous vehicles and enabling eye surgeries, lasers play a crucial role in our modern lives. But have you ever wondered how it’s possible to shape and control laser light so precisely? Enter laser optics, a specialized field that designs and applies optical components for managing laser light.

In this blog post, we take you to the fascinating realm of laser optics. We explain to you the fundamentals of laser optics and its various components. We also cover the key highlights of the laser optics market. Additionally, we explore the applications of laser optics and how advanced technologies are transforming the field. Continue reading!

What Are Laser Optics?

Laser optics are components that are specifically intended for the manipulation of laser light, which typically comes from light sources like laser diodes. The laser light manipulated by these devices is typically monochromatic and coherent. The light can also be polarized and sometimes of high intensity. The forms and applications of laser optics are highly diverse, which makes it hard to generalize about them. However, they must all be fabricated to high precision to function properly.

What Are Key Components of Laser Optics?

Laser optics encompasses several key components that enable the control and manipulation of laser beams. Below, we’ve explained them in detail:

Lenses

In laser optics, lenses are refractive transmissive optics. They are responsible for concentrating or spreading light in one or two directions. Laser lenses are typically used with monochromatic light, addressing the challenge of chromatic aberration. As such, simple single-element lenses are often good enough. This is especially true when the light is going through the center of the lens. These types of lenses are commonly used in devices like focusing optics and beam expanders. Some single-element lenses can be designed with non-spherical surfaces to achieve nearly perfect focusing. However, more complex scenarios need the use of multi-element lens systems.

Mirrors

Mirrors are used for reflecting and controlling laser beams in laser optics. There are two main types of mirrors used for lasers: metal-coated lasers and thin-film-coated lasers. Metal-coated mirrors come with a coating of metals like gold, copper, aluminum, or silicon. These mirrors are known for their cost-effectiveness and easy fabrication. Metal-coated mirrors work well for a wide range of wavelengths, but they have lower resistance to laser damage. Thin-film-coated mirrors are used in applications where high precision is required. The coatings of these mirrors are made by stacking multiple thin layers. The stacking is such that the layers of materials have alternative high and low refractive indexes.

Beamsplitters

In laser optics, beamsplitters are responsible for dividing an incoming laser beam into two parts. Here, some of the laser light is reflected while the other is transmitted through the optic. This splitting behavior can be largely based on the polarization of the laser light. In some instances, this can be a disadvantage as it causes uneven splitting based on polarization. But polarization sensitivity is also useful in other applications. Beamsplitters can also be designed to work based on wavelength. In this case, they reflect one wavelength and transmit the other. This is useful in applications having two laser beams at different wavelengths travelling in the same direction.

Polarization Components

The light emitted by most lasers is polarized. There are various devices and optics designed for manipulating, analyzing, or exploiting this polarization. The optic with the simplest concept is the linear polarizer. It allows the passage of light from only a specific polarization direction and blocks light polarized in other directions. A linear polarizer can be used to perform various functions. Another common optical component used for modifying the polarization state is the wave plate. The wave plate changes linearly polarized light into circularly polarized light, or vice versa. In applications that need more control, components like polarization rotators and linear polarizers can be combined to create a Faraday isolator. This is especially important in high-power industrial lasers.

What Are Major Market Highlights?

Our latest analysis reveals the laser optics market to register sustained growth in the coming years. The market was valued at USD 9.18 billion in 2024. It is anticipated to register a CAGR of 11.6% between 2025 and 2034.

What Are the Applications of Laser Optics?

The precision and controllability of laser optics make them widely applicable across various fields. Below, we’ve explained them in detail:

Industrial Manufacturing

Laser optics play a crucial role in modern manufacturing. Laser processing allows for precise and efficient manufacturing of materials. Key applications include laser cutting, marking, welding, drilling, and surface texturing. They offer various advantages over traditional materials in terms of speed and material compatibility. Lasers also find uses in additive manufacturing and quality control processes.

Medical Applications

Laser optics are extensively used in medicine for both diagnostic and therapeutic purposes. These applications take the form of eye surgery, tumor removal, and non-invasive treatments like skin rejuvenation and tattoo removal. Medical lasers also play a crucial role in diagnostics, where they help with tissue analysis and monitoring the effectiveness of treatments.

Scientific Research

In scientific research, lasers act as essential tools for analyzing material composition by studying the interaction of light. They are also used for creating three-dimensional images and studying molecular structures.

How AI is Transforming Laser Optics?

Artificial intelligence (AI) and machine learning (ML) are significantly improving the laser optics market. AI algorithms are being used to analyze large datasets and refine the design of optical elements for specific applications and performance needs. These algorithms can also detect anomalies and predict potential failure in laser systems. That way, they allow for preemptive maintenance actions and reduce downtime. Furthermore, AI-driven robotic systems are used for automated assembly and testing of photonic devices. Their use ensures high precision and manufacturing efficiency.

To Sum It Up

In conclusion, laser optics are the foundation of modern laser systems. Their ability to control how laser light is focused, directed, and split allows lasers to perform with high accuracy and efficiency. In the coming years, we can expect to see key players in the laser optics market introducing advanced laser optics to cater to diverse needs and applications.