Top 7 Slip Ring Manufacturers in Global Market 2025 | Here's Everything need to know About

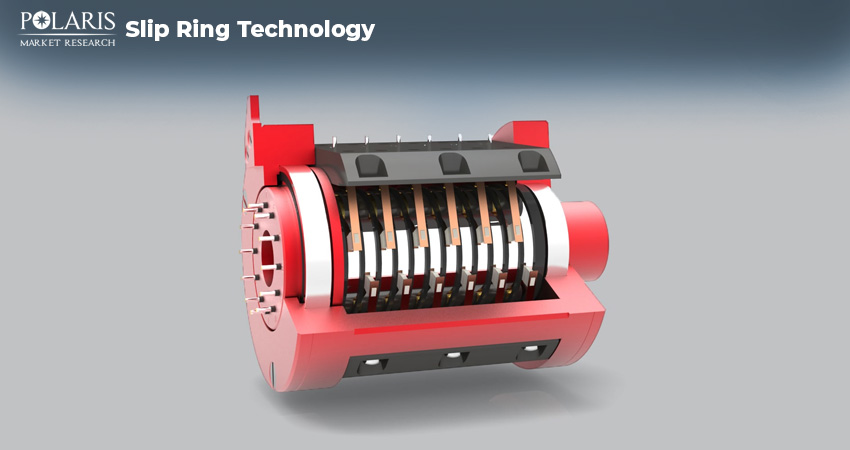

We are living in a world where the power and data flow seamlessly between stationary and rotating components in a piece of machinery, enabling complex machinery to operate efficiently and as a reliable source. This is the world of slip rings, a device able to facilitate electrical signals and power across rotating surfaces.

Slip rings are used in various types of machinery involving rotatory functions, such as wind turbines or giant Ferris wheels, to keep everything running seamlessly. Despite being small in size, they play a vital role across numerous industries, from medical devices and robotics to defense and renewable energy sources.

In this blog, we will delve into the world of slip rings, exploring the history behind them, their applications, the latest trends that are shaping their future, and key players that are governing the direction of the slip ring market.

What Are Slip Rings and Why Are They Important?

Slip rings are a type of electromagnetic device that is able to facilitate the transfer of electrical signals and power from a stationary part to a rotating part within a system. They allow continuous rotation without breaking electrical or data signals, making them essential for machinery that requires continuous rotation. Slip rings are used widely in wind turbines, CT scanners market, packaging machines, robotic arms and other rotating equipment. In each of these applications, they are expected to be durable, reliable, and provide continuous, precise performance in order to run an uninterrupted operation.

The slip ring market has witnessed robust growth due to advancements in automation, increasing adoption of renewable energy sources, and rapid development in industries that require sophisticated rotating machinery. As the world is leaning more and more towards automation and green energy, demand for efficient slip rings is constantly on the rise.

Which Are Key Slip Ring Market Companies?

Moog Inc: Moog is recognized as a prominent manufacturer of high-performance slip rings, with applications in the aerospace, defense, and industrial automation markets. Moog is known for precise and dependable slip rings used in mission-critical applications, such as radar systems for security agencies.

Schleifring GmbH: Schleifring is highly regarded for innovation in hybrid and fiber-optic slip rings, with strong applications in defense and aerospace. Their hybrid slip rings allow power and data to operate simultaneously in advanced design applications, such as airplane radar.

MERSEN: MERSEN is known for slip rings for heavy industrial applications, such as wind turbines, cable reels, or packing machines. MERSEN is particularly known for "green" slip rings that support green technology industries, particularly renewable energy, with slip rings that provide durable, sustainable products.

Rotac Co., Ltd.: Rotac is recognized as a manufacturer of high-precision slip rings, operating particularly in the robotics and medical device. Rotac’s slip rings perform well on an automated production line, or any telecommunications application, where data precision is a high priority.

Cobham Advanced Electronic Solutions: Currently a part of Advent International, Cobham manufactures rugged slip ring products for aerospace, defense, and medical applications. Cobham's slip rings are used in critical mission equipment, including military helicopters, and equipment for space exploration.

Michigan Scientific Corporation: The company offers instrumentation-grade slip rings designed for transferring analog and digital signals from sensors in rotating applications. Its slip rings are known to offer dependable signal connections.

Electro-Miniatures Corporation: The company provides high-performance slip ring assemblies for military and aerospace applications. It has several decades of experience and a large library of different designs.

What Are Latest Advancements in Slip Rings?

Miniaturization and Precision Engineering: With the advancements that sectors like the aerospace robotics market and medical technologies are witnessing, demand for compact, highly precise slip rings is on the rise. These are the fields where the equipment being used needs to be exceptionally reliable, as there is always a high-stakes environment there. This has led manufacturers to build smaller, lighter, and more durable types of slip rings that are able to deliver high-quality data transmission. Precision engineering and material science have enabled slip rings to be more compact without impacting their performance. Hence, making them more useful in applications for robotic surgeries, drones, and portable medical devices.

Focus on High-Speed and High-Frequency Performance: Certain applications, such as radar systems and high-speed machinery, require slip rings that are able to handle high-speed rotations and high-frequency data transmissions. High-frequency slip rings minimize signal distortion and improve the accuracy of data transmission, which is vital in the defense, aerospace, and automotive testing industries.

Adoption of Wireless Slip Ring Technology: While traditional slip rings rely on physical contact for data and power transmission, wireless slip rings offer an alternative that eliminates wear-and-tear issues associated with continuous contact. Wireless slip rings use electromagnetic induction or capacitive coupling to transfer data. They are particularly valuable in high-maintenance applications like wind turbines, where reduced maintenance can lead to cost savings. Although it's still an emerging technology, wireless slip rings are gaining popularity in sectors where reliability and low-maintenance operations are critical.

Integration of Fiber Optics and Transmission of Data: The rise in the need for high-speed data transmission in modern industries has led to an increased demand for slip rings with incorporated fiber-optic technology. Fiber optic slip rings enable large-volume data transfer at high speed, essential for applications in sectors like defense, telecommunications, and medical imaging equipment market, where fast and accurate data is critical.

Sustainable and Eco-friendly Manufacturing Practices: As it is with many industries, sustainability is becoming one of the most focused topics in slip-ring manufacturing. Companies are focusing on adopting eco-friendly production methods, using recyclable materials, and minimizing waste production during manufacturing. This shift aligns perfectly with the goals of minimizing environmental impact and improving corporate responsibility. Few manufacturers are creating slip rings that contribute to the efficiency of green technologies, such as those used in turbines and solar tracking systems, helping further reduce the carbon footprint of the entire energy sector.

What Challenges Do Market Players Face?

The use of slip rings causes the generation of electrical noise, especially in sensitive devices. This property might be able to downplay the growth projections of the market. Manufacturers must make sure to make slip rings that do not interfere with the overall performance of the equipment in which they are going to be incorporated. Also, the cost of premium-quality, high-grade slip rings is quite high, which is again a big factor that might have an impact on its growth.

Extreme environmental conditions pose a grave challenge to the performance of slip rings. Especially the use of slip rings in outdoor function management, like construction sites and mining operations, may lead to exposure of slip rings to corrosive chemicals or an atmosphere that is explosive, which may affect the performance of slip rings negatively and bring their efficiency down.

To Wrap it Up

Slip rings are a crucial part of rotating machines that enable them to perform seamless operations. The future of the slip ring market is expected to continue growth, thanks to automation, renewable energy, and advanced robotics. Wireless and fiber-optic slip rings present new opportunities for high-data applications, especially in IoT and data-intensive fields.