Coating Additives Market Share, Size, Trends, Industry Analysis Report, By Function (Wetting & Dispersion, Anti-Foaming, Biocides, Rheology Modification); By Formulation; By Application; By Region; Segment Forecast, 2024 - 2032

- Published Date:Mar-2024

- Pages: 115

- Format: PDF

- Report ID: PM1120

- Base Year: 2023

- Historical Data: 2019-2022

Report Outlook

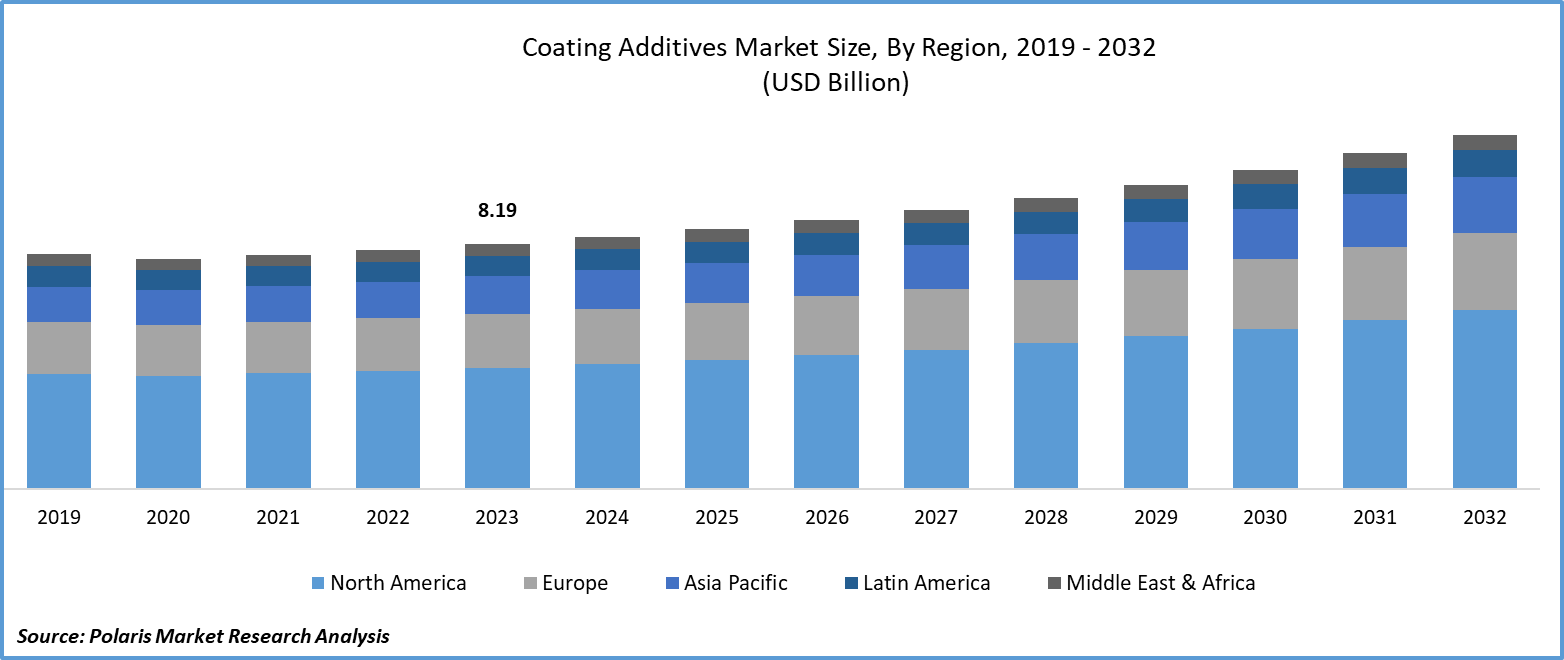

Global coating additives market size was valued at USD 8.19 billion in 2023. The market is anticipated to grow from USD 8.42 billion in 2024 to USD 11.86 billion by 2032, exhibiting the CAGR of 4.4% during the forecast period

Coating Additives Market Overview

The coating additives market development is experiencing a surge in demand due to the growing emphasis on environmental sustainability. Strict environmental regulations are compelling businesses to innovate and offer environmentally friendly products. Additionally, many countries are implementing stricter regulations regarding volatile organic compounds (VOCs), hazardous air pollutants, and their overall environmental impact. These regulations are influencing the formulation of coatings by encouraging producers to transition to low-VOC, bio-based, and water-based additives, thereby reducing the environmental footprint of coatings.

- For instance, in February 2024, Allnex is set to reveal its newest environmentally friendly coatings at PAINTINDIA 2024.

To Understand More About this Research: Request a Free Sample Report

Moreover, rising consumer awareness and preference for environmentally friendly products are boosting demand for sustainable solutions. This trend is influencing the growth dynamics of the coating additives market and compelling businesses to adopt greener practices. Furthermore, in a competitive market, extensive research and development (R&D) efforts to create new additive formulations that meet both high-performance standards and ecological objectives offer opportunities for innovation and market differentiation, leading to a promising outlook for the market.

However, the automotive and aerospace sectors require high-performance coatings to protect surfaces from wear, corrosion, and harsh environments. There is significant potential for coating additives that enhance adhesion, scratch resistance, durability, and UV protection in these industries. Producers of coating additives are expected to capitalize on this coating additives market opportunity by providing additives that meet the stringent specifications of various industries, as the demand for high-performance coatings is expected to rise.

Coating Additives Market Dynamics

Market Drivers

Growing demand of eco-friendly products is projected to spur the product demand.

Manufacturers are leading the charge in adopting innovative strategies to drive a significant transformation. By incorporating bio-based additives, they are boosting the environmental sustainability of coatings, appealing to environmentally conscious consumers who prioritize eco-friendly products. This evolution reflects a harmonious alignment between consumer preferences and industrial responsibility in the coating additives market. Increasingly, consumers are opting for cleaner and sustainable formulations to meet their coating and decorative needs, echoing the global emphasis on sustainability within the industry. The surge in demand for eco-friendly solutions, both from consumers and businesses, is propelling the adoption of bio-based alternatives, highlighting the urgent necessity for chemicals that minimize their environmental impact.

Growing Need across a Range of Industries

The coating additives market growth is driven by increasing demand from various end-use sectors such as industrial applications, wood products, automotive, and construction. Particularly, the automotive industry utilizes additives to enhance the longevity, appearance, and durability of car coatings, impacting consumer satisfaction and vehicle lifespan. Additionally, the construction sector is increasingly relying on these additives to improve the performance and aesthetics of architectural coatings, which are crucial for both protective and decorative purposes. With urbanization and industrialization on the rise globally, there is a growing need for coatings that can withstand harsh environments, resist corrosion, and maintain their visual appeal over time. This is driven by increased investments in infrastructure and manufacturing resulting from these trends.

Market Restraints

Fluctuations in prices of raw material is likely to impede the market growth

Industry stakeholders are increasingly concerned about the unpredictable price fluctuations of essential raw materials used in coating additives. These fluctuations create significant challenges for production systems, leading to higher costs and reduced profit margins. There is a risk that these challenges could restrict coating additives market expansion. To address this unstable landscape, producers must devise innovative strategies. In addition to mitigating the impact of price fluctuations, the strategic decisions of market participants will be crucial in advancing the coating additives market toward greater resilience and sustainable growth in the face of volatile raw material costs.

Report Segmentation

The market is primarily segmented based on function, formulation, application, and region.

|

By Function |

By Formulation |

By Application |

By Region |

|

|

|

|

To Understand the Scope of this Report: Speak to Analyst

Coating Additives Market Segmental Analysis

By Function Analysis

- The wetting & dispersion segment is projected to grow at the fastest CAGR during the coating additives market forecast period. Wetting and dispersing agents play a crucial role in construction and architectural coatings by ensuring the uniform dispersion of pigments and additives, enhancing both performance and visual appeal. The increasing demand for these chemicals is driven by higher solid content is necessary for coatings to achieve improved color acceptability. Moreover, there is a simultaneous push to reduce the volatile organic compound (VOC) content in formulations to comply with stringent environmental regulations in various regions. Additionally, the market is witnessing a notable rise in the requirement for pigment-dispersing agents and higher standards for precise color reproduction. These dynamics emphasize the significance of wetting and dispersion chemicals in the coatings industry.

By Formulation Analysis

- The water-borne segment is expected to grow at the fastest growth rate over the coming years. Waterborne coatings are renowned for their environmental friendliness, largely due to their lower volatile organic compound (VOC) content compared to solvent-borne coatings. Additives for waterborne coatings are extensively used in industries where reducing VOC emissions and environmental impact are critical, such as wood and furniture, packaging, automotive, and architectural coatings. Manufacturers seeking growth opportunities will find significant potential in this category. The increasing demand for waterborne coating additives is driven by consumers' heightened awareness of hazardous chemicals in paints, making this industry both attractive and responsive to environmental concerns.

By Application Analysis

- Based on application analysis, the market has been segmented on the basis of Industrial, Wood & Furniture, Architectural, Automotive & Transportation and Others. The architectural segment is expected to grow at the fastest CAGR during the coating additives market forecast period. In the coating additives industry, the architectural sector is poised for rapid growth. Coating additives play a vital role in safeguarding building structures against environmental damage. By enhancing both the aesthetic appeal and protective capabilities of structures, these additives provide essential defense against dampness, UV rays, chipping, and related issues. They significantly enhance the performance of architectural coatings, improving key attributes such as weather resistance, durability, and overall attractiveness. This makes architectural coatings a pivotal market segment, crucial for the construction and maintenance of infrastructure and buildings.

Coating Additives Market Regional Insights

The North America region dominated the global market with the largest market share in 2023

The North America region dominated the global market with the largest market share in 2023 and is expected to maintain its dominance over the anticipated period. A discerning consumer base, stringent environmental regulations, and advancements in technology are propelling the North American market. Additionally, the automotive industry's progress, the burgeoning manufacturing sector, and heightened investments in construction and restoration are driving the demand for top-tier coatings with specialized additives. The region is notably inclined toward innovative and sustainable coatings, with a rising preference for water- and bio-based additives. This shift is driven by stricter regulations on volatile organic compound (VOC) emissions and an increasing consumer awareness of environmental concerns.

The Asia Pacific region is expected to be the fastest growing region, with a healthy CAGR during the projected period. The Asia Pacific region offers substantial growth prospects for coating additives and is poised to become a highly attractive global market in the coming years. With advancements in house renovation methods and a surge in residential construction, the coating additives market demand in this region is expected to maintain its robust growth trajectory. The region's appeal is further enhanced by the increasing demand in key industries such as building, industrial, furniture, and automotive. Moreover, the Asia Pacific region is witnessing remarkable advancements, evident in its significant population growth and steadily improving living standards. It's important to consider factors such as increasing employment rates, rising disposable income among the population, and growing foreign investments in various economic sectors. Collectively, these elements bolster the Asia Pacific region's standing as a vibrant and promising market for the coating additives industry.

Competitive Landscape

The coating additives market is fragmented and is anticipated to witness competition due to several players' presence. Major service providers in the market are constantly upgrading their technologies to stay ahead of the competition and to ensure efficiency, integrity, and safety. These players focus on partnership, product upgrades, and collaboration to gain a competitive edge over their peers and capture a significant market share.

Some of the major players operating in the global market include:

- Allnex GMBH

- ALTANA AG

- Arkema S.A.

- Ashland Inc.

- BASF SE

- Clariant AG

- Dow Inc

- Eastman Chemical Company

- ELEMENTIS global

- Evonik Industries AG

- Lubrizol Corporation

- Momentive Performance Materials Inc

- MÜNZING Corporation

- Nouryon

Recent Developments

- In February 2024, Arkema is presenting new technologies for environmentally friendly paints and coatings at Paint India 2024.

- In October 2023, Evonik Industries AG launched a new additive, TEGO Guard 9000, as part of its Evonik coating additives range. This additive is designed to protect building facades starting from the application stage, offering weather resistance, high resistance to rain, and longer-lasting protection.

- In September 2022, BASF SE Coatings inaugurated a new research facility focused on electrophoretic dip coating at its headquarters in Münster-Hiltrup, Germany. This process also referred to as cathodic dip coating or e-coat, protects car body surfaces, edges, and cavities from corrosion. Furthermore, it smoothens the irregularities of pre-treated metal surfaces, providing an optimal base for subsequent paint layers.

Report Coverage

The coating additives market report emphasizes on key regions across the globe to provide better understanding of the product to the users. Also, the report provides market insights into recent developments, trends and analyzes the technologies that are gaining traction around the globe. Furthermore, the report covers in-depth qualitative analysis pertaining to various paradigm shifts associated with the transformation of these solutions.

The report provides detailed analysis of the market while focusing on various key aspects such as competitive analysis, function, formulation, application, and their futuristic growth opportunities.

Coating Additives Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2024 |

USD 8.42 billion |

|

Revenue forecast in 2032 |

USD 11.86 billion |

|

CAGR |

4.4% from 2024 – 2032 |

|

Base year |

2023 |

|

Historical data |

2019 – 2022 |

|

Forecast period |

2024 – 2032 |

|

Quantitative units |

Revenue in USD billion and CAGR from 2024 to 2032 |

|

Segments covered |

By Function, By Formulation, By Application, By Region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America; Middle East & Africa |

|

Customization |

Report customization as per your requirements with respect to countries, region and segmentation. |

FAQ's

key companies in Coating Additives Market are AG, ALTANA AG, BASF SE, Dow Inc, Nouryon, Arkema S.A., ELEMENTIS global, Allnex GMBH

Coating Additives Market exhibiting the CAGR of 4.4% during the forecast period

The Coating Additives Market report covering key segments are function, formulation, application, and region.

key driving factors in Coating Additives Market are • Growing Need across a Range of Industries

The global coating additives market size is expected to reach USD 11.86 billion by 2032