Electric Heat Tracing Market Share, Size, Trends, Industry Analysis Report

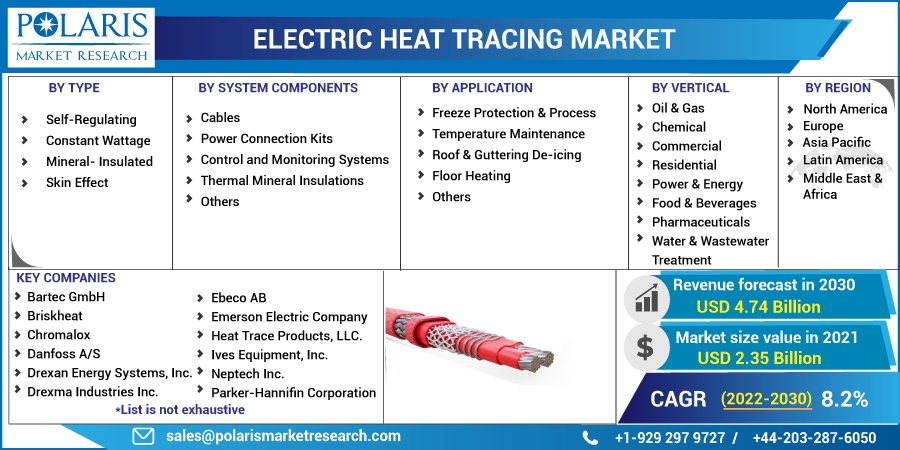

By Type (Self-Regulating, Constant Wattage, Mineral Insulated, Skin Effect); By System Components; By Application; By Vertical; By Region; Segment Forecast, 2022 - 2030

- Published Date:Oct-2022

- Pages: 117

- Format: PDF

- Report ID: PM2719

- Base Year: 2021

- Historical Data: 2018-2020

Report Outlook

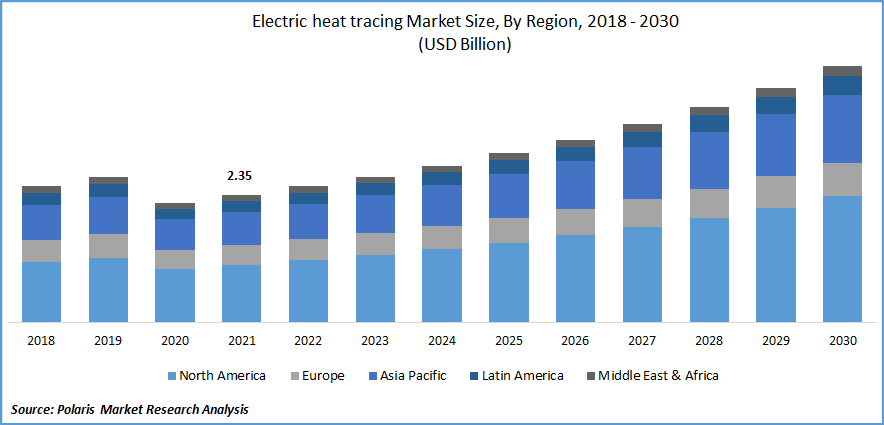

The electric heat tracing market was valued at USD 2.35 billion in 2021 and is expected to grow at a CAGR of 8.2% during the forecast period. The growing adoption of electric heat tracing systems over traditional steam tracing systems has witnessed the market’s growth.

Know more about this report: Request for sample pages

Also, factors such as the rising demand for energy-efficient electric heat tracing systems and the low maintenance cost of electric heat tracing systems have anticipated the market’s growth.

Electric heat tracing is the process of using heat tracing cables to raise the temperature level of floors, pipes, tanks, and other infrastructure surfaces. These are important areas where temperatures can drop significantly and freeze vessels, pipes, and other industrial components.

In addition, rising demand for heat tracing systems from various end-user industries and increasing adoption of heat tracing systems in power plants are expected to create growth opportunities during the forecast period.

However, overlapping heating cables and the devastating impact of installing heat tracing systems for tanks and large vessels are hindering and challenging the market growth.

Covid-19 has negatively impacted the market as the key players have reduced their production levels during the pandemic. The oil and gas sector has reduced capital expenditure with canceled ongoing projects decreasing the market’s growth.

Know more about this report: Request for sample pages

Know more about this report: Request for sample pages

Industry Dynamics

Growth Drivers

The prominent feature that propels the market’s growth is that electric heat systems offer more variety in temperature ranges than steam heat tracing systems, have lower maintenance costs than steam heat tracing systems, and can be monitored remotely. The heat tracing system requires minimal maintenance and can be replaced without damaging existing structures.

Increasing adoption of permanent heating solutions and systems by many applicable industries and decreasing costs associated with operation and maintenance are factors influencing the growth of the market.

Additionally, increasing preference for these systems over traditional steam tracking methods and the growing interest of various industries in adopting resource-efficient heating systems are factors driving the market's growth rate.

Moreover, EHT benefits various industrial sectors, including petrochemical plants, refineries, pharmaceutical manufacturing, power generation, water and waste treatment facilities, and food processing. Increasing demand for heat tracing systems and emerging new markets create more lucrative opportunities for market growth.

Report Segmentation

The market is primarily segmented based on type, system components, applications, vertical, and region.

|

By Type |

By System Components |

By Application |

By Vertical |

By Region |

|

|

|

|

|

Know more about this report: Request for sample pages

Self-regulating accounted for the largest market share in 2021

The self-regulating account for the largest market and is expected to grow fastest over the forecast as it shows applications across various verticals such as oil & gas, chemicals, commercial, and residential, among others.

Self-regulating heat tracing cables are extremely energy efficient due to their unique self-regulating feature with built-in heat tracing. The self-regulating properties of the system prevent the creation of high surface temperature, providing negligible chances of any fire hazard even in the presence of inflammable gases or liquids in and around the pipelines.

Additionally, these systems do not overheat or burn out, even in the case of the self-overlapping of cables. As these cables are used for applications including freeze protection & process temperature maintenance, floor heating, and roof & gutter de-icing, it is likely to increase the demand for self-regulating cables during the forecast period.

Electric heat tracing cable is expected to grow at fastest CAGR

Based on the system components, the market is categorized as electric heat tracing cables. Power connection kits, control and monitoring systems, thermal mineral insulations, and others. The electric heat tracing cables is expected to grow fastest over the forecast.

These cables are primarily utilized in the North American region due to the coldest weather as it protects freezing of pipes and vessels. Temperature maintenance, under-floor heating, anti-condensation, pond freeze protection, soil warming, anti-cavitation, and window de-misting are major applications driving the segment’s growth.

Freeze protection & process temperature maintenance expected to grow fastest

Based on the application, the market has been segmented for several applications, in which the freeze protection & process temperature maintenance segment is supposed to grow at the fastest CAGR.

Water or chemical pipelines often require heat tracing to prevent freezing in cold climates. Insulation alone does not prevent freezing. A 25mm diameter pipe at 5°C with 25mm thick insulation will freeze within an hour at an ambient temperature of -10°C. For instance, at 150°C, steam is not a viable fuel source for simple antifreeze. Low power electric heat tracing is the most convenient and efficient option.

Mainly the freezing problems occur in the region of North America. The temperature control is achieved by ambient air sensing or pipe sensing control. Ambient air sensing is recommended during a large amount of winterization. Growing utilization of this systems with ambient air sensing for temperature control is expected to drive the segment’s growth.

Oil & gas segment is expected to grow at highest CAGR

The oil & gas segment is expected to account the largest market share over the forecast period as this industry uses electric heat tracing for several applications such as freeze protection, viscosity control, and temperature maintenance. Heat tracing maintains the temperature or viscosity of liquids to prevent component separation and gas condensation.

So, in the oil & gas industry, heat tracing is used to prevent pipes, tanks, and vessels in cold climates and to maintain process temperatures in different areas according to requirements.

The global increase in automation and industrialization is expected to drive the growth of the market in the coming years.

Furthermore, the increasing demand for permanent heating solutions, coupled with the growing interest in minimizing operating costs, is likely to replace conventional heating systems in all industries. This is expected to impact market growth in the coming years positively.

North America is expected to grow significantly during the forecast period

The North American market is expected to rise considerably during the forecast period. North America is the coldest region compared to the Asia Pacific, the Middle East, and Africa. Due to cold weather, the demand for electric heat tracing to prevent the freezing of pipes and vessels has driven the market in this region.

Electric heat tracing is increasingly used in these countries for applications such as frost protection, floor heating, and roof & gutter de-icing. The US is expected to be the most significant contributor to this region. The presence of major players in the US is expected to propel the growth of the market in the region.

Moreover, the Asia Pacific is expected to grow fastest during the forecast due to rapid industrialization and expanding oil & gas pipeline infrastructure.

Competitive Insight

Some of the major players operating in the global market include Anhui Huanrui Heating Manufacturing Co., Ltd., Bartec GmbH, Briskheat, Chromalox, Danfoss A/S, Drexan Energy Systems, Inc., Drexma Industries Inc., Ebeco AB, Emerson Electric Company, Heat Trace Products, LLC., Ives Equipment, Inc., Neptech Inc., Parker-Hannifin Corporation, Pentair PLC, Perma-Pipe, Inc., QmaxTest Research Corporation, SST Group, Inc., Technitrace, Thermon, Tracelec, Urenco Limited, Warmup Plc, and Wuhu Jiahong New Materials Co., Ltd.

Recent Developments

In March 2020, Thermon launched ultra-high temperature and self-regulating electric heart tracer that provides superior performance & reliability and thermal stability during outperforming self-regulating competition for high temperature power outputs.

Electric Heat Tracing Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2022 |

USD 2.52 billion |

|

Revenue forecast in 2030 |

USD 4.74 billion |

|

CAGR |

8.2% from 2022 - 2030 |

|

Base year |

2021 |

|

Historical data |

2018 - 2020 |

|

Forecast period |

2022 - 2030 |

|

Quantitative units |

Revenue in USD billion and CAGR from 2022 to 2030 |

|

Segments covered |

By Type, By System Component, By Application, By Vertical, By Region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America; Middle East & Africa |

|

Key companies |

Anhui Huanrui Heating Manufacturing Co., Ltd., Bartec GmbH, Briskheat, Chromalox, Danfoss A/S, Drexan Energy Systems, Inc., Drexma Industries Inc., Ebeco AB, Emerson Electric Company, Heat Trace Products, LLC., Ives Equipment, Inc., Neptech Inc., Parker-Hannifin Corporation, Pentair PLC, Perma-Pipe, Inc., QmaxTest Research Corporation, SST Group, Inc., Technitrace, Thermon, Tracelec, Urenco Limited, Warmup Plc, Wuhu Jiahong New Materials Co., Ltd. |