Prepreg Market Share, Size, Trends & Industry Analysis Report

By Fiber Type; By Resin (Thermoplastic and Thermoset); By Manufacturing Process; By Application; By Region; Segment Forecast, 2025 - 2034

- Published Date:Jun-2025

- Pages: 115

- Format: PDF

- Report ID: PM2129

- Base Year: 2024

- Historical Data: 2020-2023

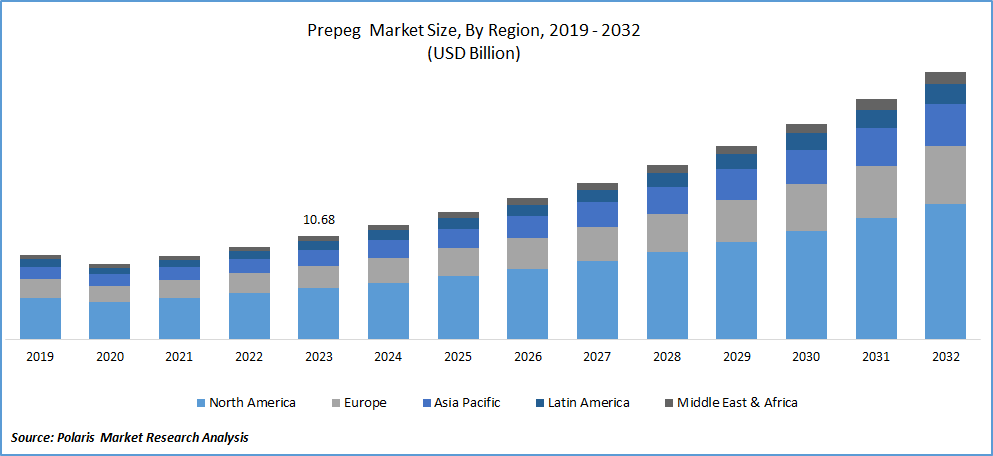

The global Prepreg Market was valued at 7.45 billion in 2024 and is projected to grow at a CAGR of 8.50% from 2025 to 2034. Strong demand from aerospace, automotive, and wind energy sectors for lightweight, high-strength composite materials is accelerating the market's expansion.

Industry Overview

Prepregs are composite materials featuring a high-performance reinforcement fiber pre-impregnated with a thermoplastic or thermoset resin, typically epoxy, with a suitable curing agent. This preimpregnation eliminates the need for additional resin during the molding process. Prepregs find extensive applications in sporting goods, racing, aerospace, and various commercial products.

The prepreg market size driven by their versatile attributes, including lightweight construction, enhanced fuel efficiency, reduced material consumption, and lower emissions. Their outdoor durability makes them particularly suitable for applications in the logistics and construction industries, contributing to increased popularity and adoption among end users.

Carbon fiber prepreg, a lightweight variant containing carbon fibers, offers additional mechanical benefits such as high strength, low density, and modulus of elasticity compared to other fiber prepregs. The increasing demand for carbon fiber prepreg is anticipated to fuel the overall industry opportunity.

To Understand More About this Research:Request a Free Sample Report

Prepregs exhibit exceptional properties, including high impact resistance and a superior strength-to-weight ratio, making them effective for manufacturing composite parts for both primary and secondary aircraft structures. This has led to their widespread use in the aviation industry, particularly in helicopters, defense aircraft, and aero engines, contributing to prepreg market expansion.

For instance, In February 2020, Solvay introduced CYCOM EP2750, a high-rate compression molding prepreg especially designed for aerospace preliminary designs. This technique integrates advanced fiber prepreg materials, showcasing Solvay's commitment to innovation in the aerospace sector.

Despite their advantages, the high manufacturing costs associated with raw materials like aramid, carbon, and glass fibers used in prepreg production can impact final product prices, posing a potential challenge to market growth. However, the industry is witnessing a rise in the adoption of advanced processing and assembly techniques aimed at minimizing lead times and enhancing product quality, which is expected to counterbalance these challenges.

The prepreg market Key players hold a significant presence across the value chain, encompassing raw material supply and product manufacturing. This strategic positioning allows them to secure raw materials at competitive prices, gaining a competitive edge. Additionally, companies are actively investing in research and development to create high-quality products, thereby stimulating overall prepreg market growth.

Key Takeaways

- North America dominated the largest revenue and contributed to more than 45% of share in 2023

- Europe region is expected to grow at fastest CAGR during the forecast period

- By fiber type category, carbon fiber segment accounted for the largest market share in 2024

- By application category, the aerospace segment accounted for the high market share in 2024.

What are the Market Drivers Driving the Demand for Prepreg Market?

Rising Demand of Light Weight Vehicle

The surge in demand for lightweight vehicles stands out as a primary driver for the increased sales of prepreg. According to a report from the U.S. Department of Energy, a 10% reduction in automobile weight can yield a notable 6% to 8% improvement in fuel economy. Prepreg-based composites offer a practical and lightweight alternative to metals.

In the automotive sector, thermoplastic-based tapes featuring continuous carbon fiber reinforcements find application in both the exterior and interior of vehicles. Prepregs, typically lighter than their counterparts, contribute to a significant reduction in automobile weight, fostering enhanced fuel efficiency, decreased emissions, and minimized material usage in transportation applications. This trend is expected to fuel the demand for lightweight materials like prepregs in the foreseeable future which ultimately increase the industry growth.

Furthermore, the expanding application scope across various industries, including aerospace, marine, construction and infrastructure, wind energy, and sporting goods, among others, presents numerous growth opportunities for the prepreg market in the upcoming forecast period.

Which Factor is Restraining the Demand for Prepreg?

Complex Manufacturing Processes

The manufacturing of prepregs involves precise control over temperature, pressure, and curing conditions. The complexity of the manufacturing process can lead to challenges in scaling up production and may require specialized equipment and expertise. The use of certain resins and chemicals in prepreg manufacturing may raise environmental and regulatory concerns. Compliance with environmental regulations and the need for sustainable practices could pose challenges for the prepreg industry.

Report Segmentation

The market is primarily segmented based on resin, fiber type, manufacturing process, application, and region.

|

By Resin |

By Fiber Type |

By Manufacturing process |

By Application |

By Region |

|

|

|

|

|

To Understand the Scope of this Report:Speak to Analyst

Category Wise Insights

By Fiber Type Insights

Based on fiber type analysis, the market is segmented on the basis of glass fiber, aramid fiber, carbon fiber and others. In 2023, the carbon fiber segment accounted for the largest prepreg market share, owing to its exceptional properties and extensive applications across various industries such as wind energy, sporting goods, automotive, and aerospace. The projected period is expected to witness continued revenue growth in this segment, driven by the increasing demand for lightweight and high-performance materials.

Furthermore, the glass fiber segment is poised to maintain a steady rate of revenue growth throughout the projected period, attributed to its flexibility and cost-effectiveness. Glass fibers find widespread use in the construction industry, particularly in the production of glass wool, a common material for thermal insulation. Additionally, the expanding market for renewable energy sources is expected to boost demand for glass fibers, particularly in the growing wind energy sector.

By Application Insights

Based on application analysis, the market has been segmented on the basis of automotive, aerospace, electronics, wind energy and others. In 2023, the aerospace segment accounted for the highest prepreg market share. The heightened opportunity for prepreg fibers in the aerospace industry is driven by the increasing necessity for aircraft components that are both highly durable and lightweight. The aerospace sector widely prefers prepreg materials for manufacturing various parts and components, as they facilitate a consistent resin ratio throughout the finished product. This characteristic enhances the mechanical and physical properties of the end components. Moreover, the segment's growth is expected to be fueled by the escalating production of commercial aircraft in response to the rising passenger traffic.

Prepreg fibers are rapidly being adopted as an option to organic fiber and metal wire in structural composite applications within the automotive industry. This preference is attributed to their superior mechanical properties compared to other synthetic fibers. Furthermore, the growing demand for batteries in the automotive sector is anticipated to contribute to the increasing demand for prepreg materials.

Regional Insights

North America

In 2023, North America dominated the largest revenue share. It is anticipated that the area will supply around one-third of the world's operational fleet requirements, which will boost airframe and aircraft part production over the next ten years. Throughout the projected period, the growth of the aircraft manufacturing industry is expected to support the growth of the regional market as demand for new-generation aircraft increases.

Furthermore, the automotive and wind energy sectors are also key contributors to the demand for prepregs in North America. The lightweight and high-strength characteristics of prepreg materials make them suitable for applications in automotive components and wind turbine blades. As these industries continue to grow, the scope of prepreg materials is likely to expand. North America is known for its focus on research and development in advanced materials, including composites. Ongoing R&D activities contribute to the development of innovative prepreg materials with enhanced properties, driving the market forward.

Europe

Europe's market is anticipated to grow at the fastest rate during the forecast period. The automotive sector growth in the region is anticipated to be bolstered by process innovation, enhanced research and development, and increasing car manufacturing in countries like France, Germany, the United Kingdom, and Spain. Therefore, robust expansion in the automotive sector, together with the rising need for lightweight materials, is anticipated to propel market expansion in Europe. The growing number of wind energy projects in nations like the Czech Republic and Germany would enhance demand for the product.

Competitive Landscape

The market is characterized as consolidated market with few players relying on advanced technology, high-quality products, and a strong brand image to drive revenue growth. These companies employ various strategies such as research and development, mergers and acquisitions, and technological innovations to expand their product portfolios and maintain a competitive edge in the market.

Some of the major players operating in the global market include:

- Axiom Materials

- Composite Resources Inc.

- Gurit Holding AG

- Hexcel Corporation

- Isola Group

- Mitsubishi Chemical Holdings Corporation

- Park Aerospace Corp.

- Plastic Reinforcement Fabrics Ltd.

- Renegade Materials Corporation

- SGL Group

- Solvay Group

- Sunrez Corporation

- Teijin Limiteds

- Toray Industries, Inc.

- Ventec International Group

Recent Developments

- In July 2023, Hexcel launched HexPly M51 prepreg and HiFlow HF610F-2 RTM resin, enabling faster cure cycles and high-rate aerospace part production, supporting projects like Airbus’ Wing of Tomorrow and GKN Aerospace’s ASCEND.

- In May 2022, TRB Lightweight Structures and Kordsa joined forces to develop composite materials aimed at fostering the production of sustainable lightweight composites for the automotive sector. Leveraging its proprietary thermoset prepreg material, TRB has effectively delivered more than 65,000 composite components for Tier 1 automotive programs.

Report Coverage

The prepreg market size report emphasizes on key regions across the globe to provide better understanding of the product to the users. Also, the report provides market insights into recent developments, trends and analyzes the technologies that are gaining traction around the globe. Furthermore, the report covers in-depth qualitative analysis pertaining to various paradigm shifts associated with the transformation of these solutions.

The report provides detailed analysis of the market while focusing on various key aspects such as competitive analysis, resin, fiber types, manufacturing process, applications, and their futuristic growth opportunities.

Prepreg Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2025 |

USD 8.1 billion |

|

Revenue forecast in 2034 |

USD 17.2 billion |

|

CAGR |

8.50% from 2025 – 2034 |

|

Base year |

2024 |

|

Historical data |

2020 – 2023 |

|

Forecast period |

2025– 2034 |

|

Quantitative units |

Revenue in USD billion and CAGR from 2025 to 2034 |

|

Segments Covered |

By Resin, By Fiber Type, By Manufacturing process, By Application, By Region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

|

Customization |

Report customization as per your requirements with respect to countries, region, and segmentation. |

FAQ's

The key companies in Prepreg Market include Axiom Materials, Composite Resources Inc., Gurit Holding AG, Hexcel Corporation,

Prepreg Market exhibiting the CAGR of 8.50% during the forecast period.

Prepreg Market report covering key segments are resin, fiber type, manufacturing process, application, and region.

The key driving factors in Prepreg Market are Rising demand of light weight vehicle

Prepreg Market Size Worth $ 17.2 Billion By 2034 .