Screw Capping Machine Market Share, Size, Trends, Industry Analysis Report

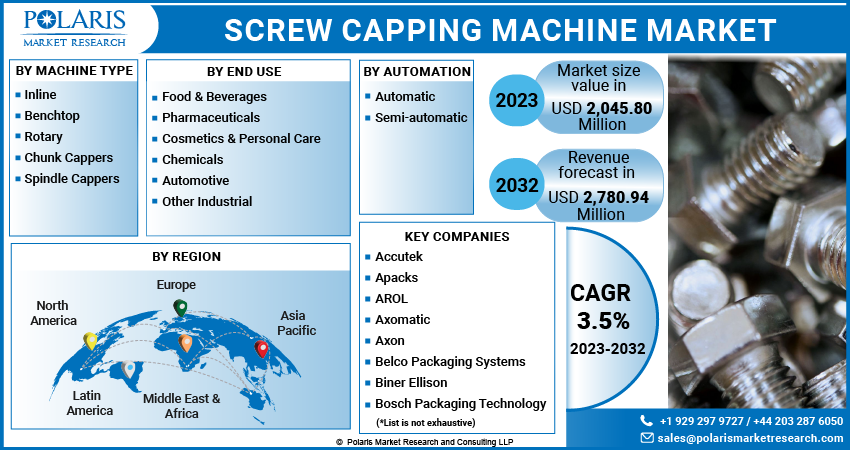

By Automation (Automatic, Semi-automatic); By Machine Type; By End Use; By Region; Segment Forecast, 2023 - 2032

- Published Date:Jul-2023

- Pages: 116

- Format: pdf

- Report ID: PM3676

- Base Year: 2022

- Historical Data: 2019-2021

Report Outlook

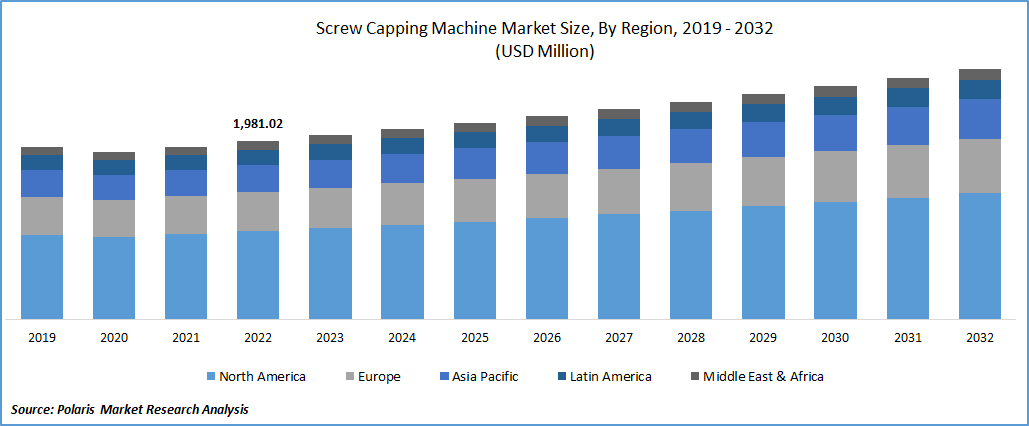

The global screw capping machine market was valued at USD 1,981.02 million in 2022 and is expected to grow at a CAGR of 3.5% during the forecast period.

Automation in screw capping machines eliminates the need for manual labor, leading to increased efficiency and productivity. These machines can cap bottles or containers much faster than manual capping, allowing manufacturers to meet high production demands and improve overall operational efficiency. Shemesh Automation introduced an unprecedented capping machine that boasts unmatched versatility.

To Understand More About this Research: Request a Free Sample Report

The ATTILUS continuous motion capping machine, combining cutting-edge robotics and an advanced vision system, is set to revolutionize the packaging machinery industry. This innovative solution pushes the boundaries of what is currently available, offering unparalleled capabilities and paving the way for enhanced packaging automation.

Industry Dynamics

Growth Drivers

Rising product innovations drives the market

Growing product innovations in the bottling industry are playing a significant role in driving the market's growth. The launch of fully accredited child-resistant PET bottle combinations by Berry for the pharmaceutical syrup market can potentially cause the development of the screw-capping machine market. These child-resistant bottles require specialized screw caps that ensure the safety of children by preventing accidental ingestion. As pharmaceutical companies increasingly prioritize the security and compliance of their packaging, the demand for screw capping machines capable of efficiently sealing these child-resistant PET bottles is likely to rise. Therefore, this development in the pharmaceutical syrup market has the potential to fuel the growth of the screw-capping machine market as manufacturers seek automated solutions to meet the packaging requirements of these specialized bottles.

For Specific Research Requirements, Speak With Research Analyst

Report Segmentation

The market is primarily segmented based on automation, machine type, end use and region.

|

By Automation |

By Machine Type |

By End Use |

By Region |

|

|

|

|

To Understand the Scope of this Report: Speak to Analyst

By Automation

Automatic segment is expected to witness fastest growth during forecast period

The automatic segment is expected to have faster growth in the market. Automatic screw capping machines are designed to perform the capping process without significant human intervention. These machines can automatically feed caps, apply precise torque, and ensure consistent sealing across a high volume of bottles. The automation provided by automatic screw capping machines offers numerous advantages, such as increased efficiency, higher production rates, reduced labor costs, and improved quality control. The demand for automatic screw-capping machines is particularly high in industries requiring large-scale production and high-speed packaging, such as beverages, pharmaceuticals, cosmetics, and food processing. These machines streamline packaging, minimize human error, and enhance productivity. The automation capabilities of automatic screw capping machines make them a preferred choice for manufacturers seeking efficient and reliable capping solutions.

By Machine Type

Rotary segment expected to have largest market share in the upcoming years

The rotary segment holds the largest market share in the study period. Rotary screw capping machines are known for their ability to handle high-speed production requirements. These machines are designed to feed bottles and caps continuously, applying precise torque and sealing them efficiently. The high-speed operation of rotary cappers enables manufacturers to achieve greater production rates, meet increased demand, and improve overall operational efficiency. While rotary screw capping machines may require a higher initial investment, their high-speed operation and efficiency make them cost-effective solutions in the long run.

The increased production rates and reduced labor requirements result in higher output and lower per-unit costs, contributing to the overall profitability of manufacturers. Rotary screw capping machines offer consistent and precise capping results. The rotating disc or wheel mechanism ensures accurate cap placement and torque application, minimizing variations and ensuring a reliable seal. Consistency and precision are crucial for maintaining product quality and meeting the stringent requirements of the pharmaceuticals and food processing industries.

By End-Use

Food & Beverages segment is expected to hold the larger revenue share during projected period

Food & Beverages segment is projected to witness a larger revenue share in the coming years. The food and beverages industry is one of the largest consumers of screw-capping machines. With the rising demand for packaged food and beverages, there is a growing need for efficient and reliable capping solutions. Screw capping devices are crucial in sealing bottles of various sizes and types, ensuring product freshness, preventing leakage, and maintaining product quality. The food and beverages industry encompasses many products, including carbonated drinks, juices, sauces, condiments, dairy products, and more. Each product has specific packaging requirements, including different bottle sizes, closure types, and cap designs.

Screw capping machines offer versatility and adaptability to cater to these diverse packaging needs, driving their adoption in the industry. Ensuring packaging safety and integrity is paramount in the food and beverages industry. Screw capping machines help maintain the seal and prevent product contamination, extending the shelf life of perishable goods. They also play a vital role in preserving carbonation in beverages. The emphasis on maintaining product quality and safety fuels this sector's demand for screw capping machines.

Regional Analysis

APAC registered with the highest growth rate in the study period

APAC is projected to witness a higher growth rate for the market. Growing innovations by manufacturers in developing countries like China and India are driving market growth in the Asia Pacific. Adinath International, a renowned manufacturer of automatic bottle cappers based in India, launched a versatile four-head bottle-capping machine. This machine, known for its robust design and superior functionality, offers reliable and precise capping solutions for various products across diverse sectors. The launch of this machine has not only met the market demand but has also stimulated further research and development activities among competitors in the screw-capping machine industry. These innovations and advancements in the market drive its overall growth, ensuring businesses access more efficient and effective packaging solutions.

North America is expected to witness a larger revenue share in the market. The increasing demand for sustainability-marketed products among consumers in the United States and other developed countries is driving the growth of the market for screw-capping machines. Therefore, the growing demand for sustainability-marketed products and global companies' emphasis on environmental responsibility is driving the development of the screw-capping machine market in this region. Manufacturers in the industry are developing innovative solutions to meet evolving packaging needs, allowing businesses to enhance their sustainability efforts and cater to the preferences of environmentally conscious consumers.

Competitive Insight

The Screw Capping Machine market is fragmented and is anticipated to witness competition due to several players' presence. Major service providers in the market are constantly upgrading their technologies to stay ahead of the competition and to ensure efficiency, integrity, and safety. These players focus on partnership, product upgrades, and collaboration to gain a competitive edge over their peers and capture a significant market share.

Some of the major players operating in the global market include:

- Accutek

- ALTech UK Labelling Technologies

- AMT- Accu-Seal Machine & Tool

- Apacks

- AROL

- Axomatic

- Axon

- Belco Packaging Systems

- Biner Ellison

- Bosch Packaging Technology

- C.E.King

- Crown

- Federal

- Filamatic

- IC Filling Systems

- ICOS Impianti Srl

- Inline Filling Systems

- In-Line Packaging Systems

- Kauffman Engineering

- KHS

- Krones

- LPS Industries

- Marchesini

- MG2

- Multipack Machinery

- Neumann Packaging Services

- NPACK Machinery

- Pacific Packaging Machinery

- Pack Leader USA

- Packaging Equipment

- R.A. Jones & Toyo Jidoki

- SACMI

- Serac

- Shree Bhagwati Machtech

- Sidel

- Technopack

- Tetra Pak

Recent Developments

- In May 2023, SACMI introduced 4 one-piece cap models, GME 30.4, to expand its wide range in the 26/22 mm family.

- In April 2023, Tetra Pak, a pioneer in carton packaging, collaborated with Elvir in France to introduce the first-ever cap for beverage cartons made from certified recycled polymers.

Screw Capping Machine Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2023 |

USD 2,045.80 million |

|

Revenue forecast in 2032 |

USD 2,780.94 million |

|

CAGR |

3.5% from 2023 – 2032 |

|

Base year |

2022 |

|

Historical data |

2019 – 2021 |

|

Forecast period |

2023 – 2032 |

|

Quantitative units |

Revenue in USD million and CAGR from 2023 to 2032 |

|

Segments covered |

By Automation, By Machine Type, By End Use, By Region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

|

Customization |

Report customization as per your requirements with respect to countries, region and segmentation. |

FAQ's

The screw capping machine market report covering key segments are automation, machine type, end use and region.

Screw Capping Machine Market Size Worth $2,780.94 Million By 2032.

The global screw capping machine market is expected to grow at a CAGR of 3.5% during the forecast period.

Asia Pacific is leading the global market.

key driving factors in screw capping machine market are growing popularity of craft breweries.