3D Printing Gases Market Share, Size, Trends & Industry Analysis Report

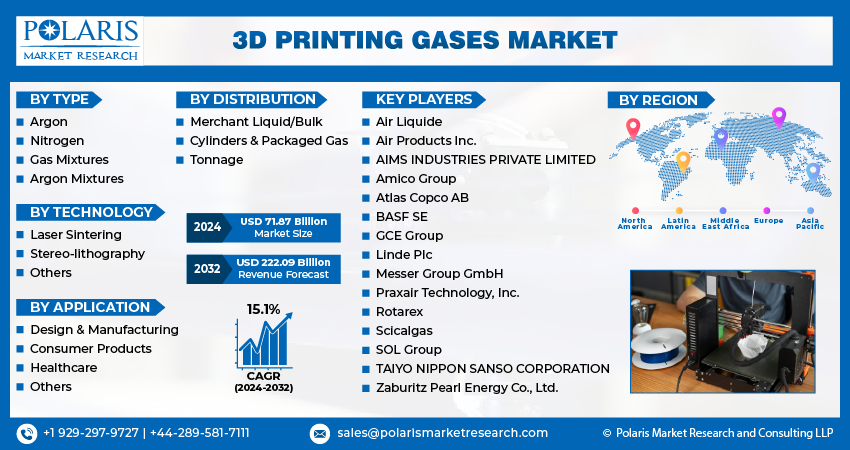

By Type (Argon, Nitrogen, Gas Mixtures, Argon Mixtures); By Technology; By Application; By Distribution; By Region; Segment Forecast, 2025 - 2034

- Published Date:Jun-2025

- Pages: 130

- Format: PDF

- Report ID: PM4171

- Base Year: 2024

- Historical Data: 2020-2023

The global 3D Printing Gases Market was valued at USD 0.7 billion in 2024 and is anticipated to grow at a CAGR of 21.50% from 2025 to 2034. Expansion in additive manufacturing and metal printing applications is a major growth catalyst.

Additive manufacturing, also known as 3D printing, is conducted in highly regulated environments to minimize the exposure of materials and processes to contaminants and ensure the production of high-quality items. To fulfill the stringent tolerance levels required in this field, gases such as argon, nitrogen, or combinations of these gases are used to create inert atmospheres.

To Understand More About this Research: Request a Free Sample Report

Several factors are driving the growth of the 3D printing gases market, such as the advancements of 3D printing technology, increasing demand for personalized products, and the surging focus on the environment friendly production practices. Additive manufacturing, also known as 3D printing, has transformed the manufacturing process by allowing for the rapid and precise creation of intricate, personalized products. The demand for 3D printing gases such as argon, nitrogen, and helium has increased due to their critical role in achieving optimal printing results.

3D printing gases are used in a variety of industries, including aerospace and defense, automotive, healthcare, food and beverages, and building and construction. Gases are critical in 3D printing for protecting work materials from the harmful effects of heat generated during production. Metals, plastics, ceramics, and wax are common materials used in this process. Argon and nitrogen are two commonly used gases that necessitate proper storage and delivery systems to ensure safe use.

COVID-19 has had an impact on nearly every sector globally as a result of the worldwide pandemic, resulting in long-term effects that are anticipated to impede overall industry growth for the forecast period. The imposition of lockdown measures on production facilities and manufacturing operations by numerous local authorities has also had a substantial impact on the 3D printing gases market. The initial disruptions in the supply chain and manufacturing processes caused a temporary slowdown in the industry. Lockdowns, travel restrictions, and labor shortages hampered the production and distribution of 3D printing gases.

The shift toward decentralized manufacturing and increased adoption of 3D printing in healthcare, aerospace, and other industries has fueled the recovery of the 3D printing gases market. As economies continue to rebound, the market is anticipated to grow steadily, fueled by ongoing technological advancements and the growing acceptance of 3D printing as a versatile and efficient manufacturing solution.

Industry Dynamics

Growth Drivers

Rising Demand for 3D Printing by Using Inert Gases will Drive the Growth of the Market

The rising demand for inert gases in the healthcare and aerospace industries in order to meet the stringent precision requirements required for 3D printing is anticipated to drive the growth of the market. Inert gases play an important role in the printing process by creating a non-reactive environment, effectively reducing oxidation of sintered components. This is accomplished by lowering the oxygen concentration and maintaining a stable printing environment by maintaining consistent pressure within the print chamber.

The enduring features of inert gases are driving the increased demand for 3D printing with gases. Using gases such as argon and nitrogen in 3D printing has several advantages, the most important of which is that it improves the overall quality of the printed items. The efficiency and stability demonstrated by the use of gases in 3D printing, especially when compared to alternative methods, are contributing to increased demand for this process in industries such as construction, healthcare, and aerospace.

Report Segmentation

The market is primarily segmented based on type, technology, application, distribution, and region.

|

By Type |

By Technology |

By Application |

By Distribution |

By Region |

|

|

|

|

|

To Understand the Scope of this Report: Speak to Analyst

By Type Analysis

The Argon Segment Accounted for the Largest Revenue Share in 2023

In 2023, the argon segment held the largest revenue share. It is owing the escalating usage for argon in the design and manufacturing industry across the world. Also, the numerous benefits of argon use consist of reduced oxidation in sintered parts, corrosion prevention and impurity exclusion, the establishment of a stable printing environment via sustained pressure, and the reduction of fire hazards by rendering combustible dust inert. These factors all contribute to the expected rise in argon demand.

Argon is the commonly utilized gas in the 3D printing, which is known for its inertness and the ability to create a controlled printing atmosphere. Argon gas protects high-quality prints with less defects and enhances material properties. It is especially suitable for the metal 3D printing processes such as electron beam melting and selective laser melting.

By Technology Analysis

The Stereolithography Segment Accounted for the Highest Market Share During the Forecast Period

The stereolithography segment held the highest market share during the forecast period, Stereolithography is a type of vat photopolymerization within additive manufacturing technologies, also known as resin 3D printing. All of these devices work on the same basic principle: they use a light source—either a laser or a projector—to solidify liquid resin into a durable plastic. The primary distinctions between these machines are in the configuration of critical components such as the light source, build platform, and resin tank.

Professionals such as designers and engineers are seamlessly incorporating 3D printing into their workflows throughout various stages of development due to increasing accessibility and affordability of the technology, as well as advancements in hardware and materials that align with market needs. 3D printing is enabling professionals in a variety of industries to reduce outsourcing costs, accelerate iteration processes, streamline production optimization, and pioneer new business models.

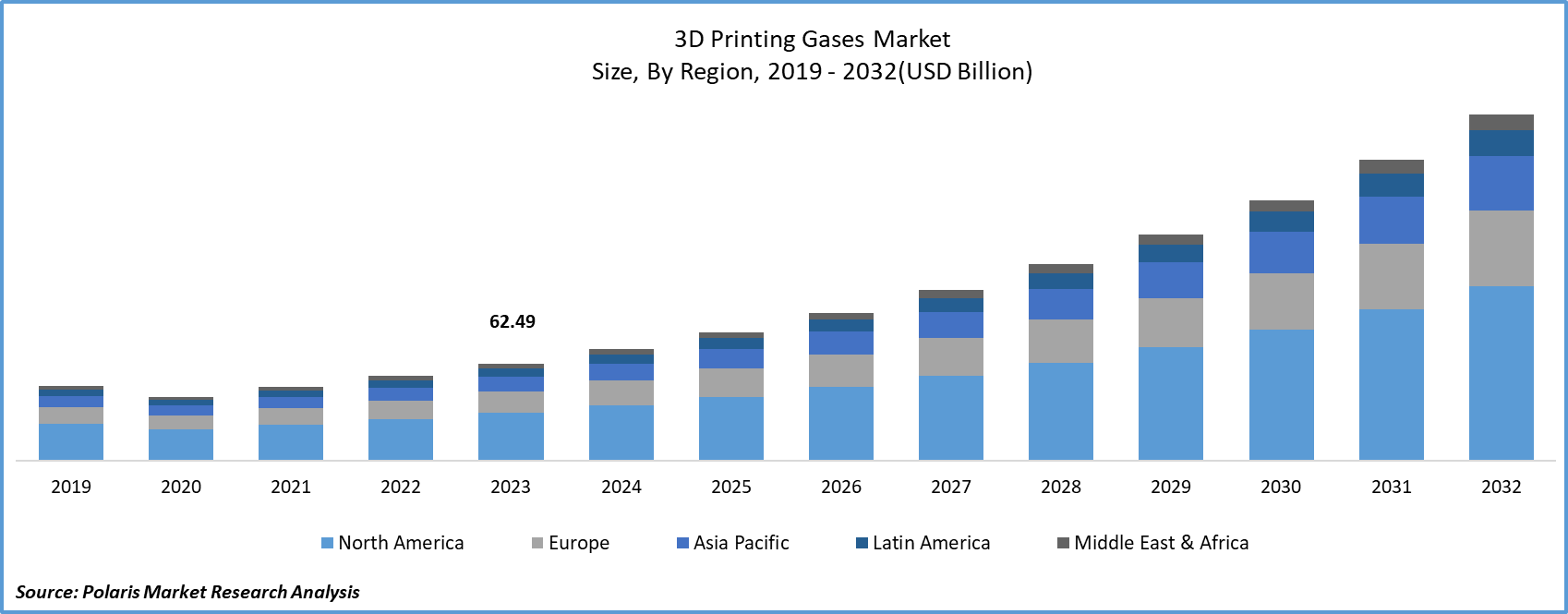

Regional Insights

North America Accounted for the Largest Market Share in 2024

In 2024, North America held the largest market share in the 3D printing gases market, owing to the region’s extensive adoption of additive manufacturing. The presence of major industrial gas companies and numerous research and development initiatives in 3D printing are driving significant growth in the North American market. This growth is aided by significant advances in product manufacturing, particularly in the healthcare and aerospace industries. Also, the region's significant investment in technological development is anticipated to boost domestic demand for 3D printing gases.

Asia Pacific is witnessed for the fastest growth in the 3D printing gases market. The expansion of the design and manufacturing sector, the growing health care business, rising demand for consumer goods and automobiles driven by population growth and economic development, and a variety of other factors are propelling the growth of the 3D printing gas market. Emerging markets in Asia Pacific, particularly China and India, offer significant potential opportunities in the global 3D printing gases market. The growing emphasis on integrating 3D printing methods into the industrial sector is a key driver of the region's 3D printing gases market growth.

Key Market Players & Competitive Insights

The market is characterized by intense competition, with established players relying on advanced technology, high-quality products, and a strong brand image to drive revenue growth. These companies employ various strategies such as research and development, mergers and acquisitions, and technological innovations to expand their product portfolios and maintain a competitive edge in the market.

Some of the major players operating in the global market include:

- Air Liquide

- Air Products Inc.

- AIMS INDUSTRIES PRIVATE LIMITED

- Amico Group

- Atlas Copco AB

- BASF SE

- GCE Group

- Linde Plc

- Messer Group GmbH

- Praxair Technology, Inc.

- Rotarex

- Scicalgas

- SOL Group

- TAIYO NIPPON SANSO CORPORATION

- Zaburitz Pearl Energy Co., Ltd.

Recent Developments

- In March 2024, Linde plc introduced a new lineup of high-purity gases designed specifically for metal 3D printing, expanding its product portfolio in the field of additive manufacturing.

- In November 2023, BASF SE, a major player in the global battery materials industry, and SK On, a leading global manufacturer of electric vehicle battery cells, have established a partnership to assess potential collaboration avenues in the lithium-ion battery market on a global scale, with a focus on North America and the Asia-Pacific region.

- In November 2021, TronHoo, a Chinese company, has launched its latest thermochromic PLA filament designed for use in desktop 3D printers.

3D Printing Gases Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2025 |

USD 0.9 billion |

|

Revenue forecast in 2034 |

USD 5.4 billion |

|

CAGR |

21.50% from 2025 – 2034 |

|

Base year |

2024 |

|

Historical data |

2020 – 2023 |

|

Forecast period |

2025 – 2034 |

|

Quantitative units |

Revenue in USD billion and CAGR from 2025 to 2034 |

|

Segments Covered |

By Type, By Technology, By Application, By Distribution, By Region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

|

Customization |

Report customization as per your requirements with respect to countries, region, and segmentation |

FAQ's

key companies in 3D printing gases market are Air Liquide, Air Products Inc., AIMS INDUSTRIES PRIVATE LIMITED, Amico Group, Atlas Copco AB, BASF SE, GCE Group, Linde Plc

The global 3D printing gases market is expected to grow at a CAGR of 21.50% during the forecast period.

The 3D printing gases market report covering key segments are type, technology, application, distribution and region.

key driving factors in 3D printing gases market are rising demand for 3D printing by using inert gases will drive the growth of the market

The global 3D printing gases market size is expected to reach USD 5.4 billion by 2034