Bio-based Epoxy Resins Market Size, Share, Trends & Industry Analysis Report

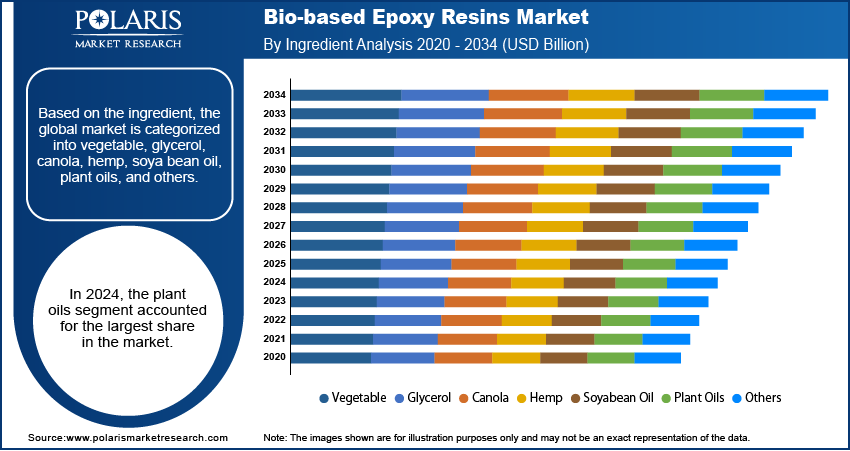

: By Ingredient (Vegetable, Glycerol, Canola, Hemp, Soyabean Oil, Plant Oils, Others), By Application, By Region -Market Forecast, 2025 - 2034

- Published Date:Sep-2025

- Pages: 103

- Format: PDF

- Report ID: PM1778

- Base Year: 2024

- Historical Data: 2020 - 2023

Overview

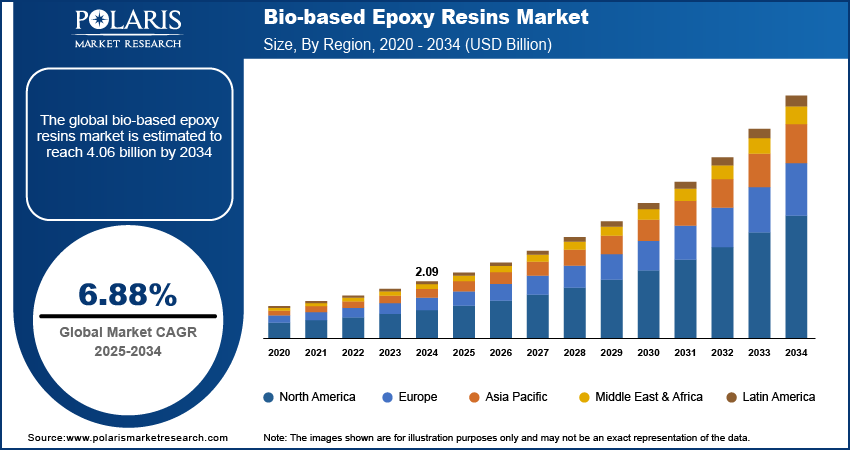

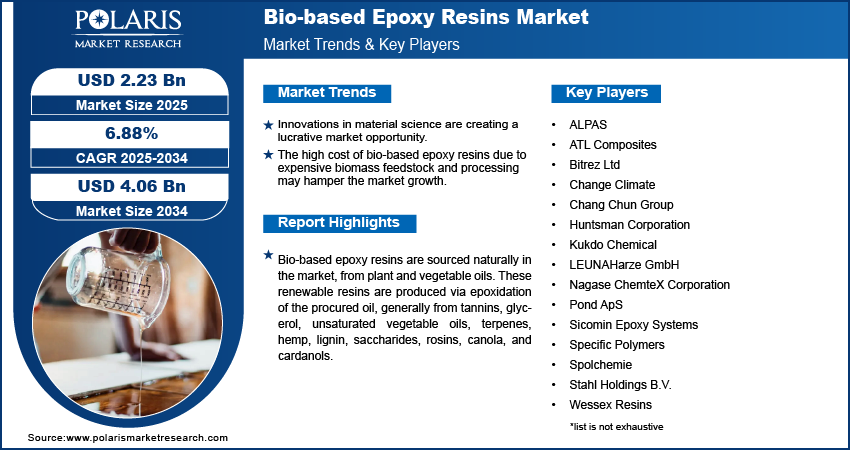

The global bio-based epoxy resins market size was valued at USD 2.09 billion in 2024 and is anticipated to grow at a CAGR of 6.88% from 2025 to 2034. Key factors driving demand for bio-based epoxy resins include strict government regulations pushing for sustainable and eco-friendly materials, increasing environmental concerns, and growing demand for durable materials in automotive, construction, and electronics.

Key Insights

- In 2024, the plant oils segment accounted for the largest share in the market. The negative impacts of fossil fuel as a feedstock and innovations in green chemistry are the prominent growth factors for this segment.

- North America accounted for a major revenue share in 2024, due to rising focus on green epoxy resin systems.

- The market in the Asia Pacific is projected to grow at a rapid pace in the coming years, owing to its positive business scenario and huge consumer base.

Industry Dynamics

- The increase in the production of automobiles and the development of high-rise towers across the globe are propelling the market growth.

- The strict government regulations pushing for sustainable and eco-friendly materials are fueling the demand for bio-based epoxy resins.

- Innovations in material science are creating a lucrative market opportunity.

- The high cost of bio-based epoxy resins due to expensive biomass feedstock and processing may hamper the market growth.

Market Statistics

- 2024 Market Size: USD 2.09 Billion

- 2034 Projected Market Size: USD 4.06 Billion

- CAGR (2025-2034): 6.88%

- North America: Largest Market Share

To Understand More About this Research:Request a Free Sample Report

AI Impact on Bio-based Epoxy Resins Market

- AI helps in optimizing bio-based epoxy resin formulations by analyzing performance data.

- Predictive modeling supports better raw material selection.

- AI enhances efficiency in resin manufacturing.

- Smart analytics assist in forecasting demand across industries.

Bio-based epoxy resins are sourced naturally in the market, from plant and vegetable oils. These renewable resins are produced via epoxidation of the procured oil, generally from tannins, glycerol, unsaturated vegetable oils, terpenes, hemp, lignin, saccharides, rosins, canola, and cardanols. A wide range of curing agents are required, also known as a hardener, in the production of epoxy resins in the market, its selection depends on its application and usage type. The key factors responsible for the market growth include the presence of varied natural resources to manufacture these resins, low cost, environment friendliness, and increasing focus of key players on the bio-based resin systems.

A curing agent is a chemical substance that participates in the cross-reaction of monomers, oligomers to carry out polymerization reaction to produce the final product in the form of resins. The selection of curing agents depends on the two important parameters viscosity and the glass transition temperature (Tg). With the help of binders and catalyst agents, curing agents form 3D structures.

The research report offers a quantitative and qualitative analysis of the bio-based epoxy resins market to enable effective decision-making. It covers the key trends and growth opportunities anticipated to have a favorable impact on the market. Besides, the study covers segment and regional revenue forecasts for market assessment. Moreover, the pressure on government regimes to stay carbon neutral in the market owing to consumer’s awareness of plastic waste and subsequent investments in the sector also played a pivotal role. For instance, Hexion Inc., an Ohio-based chemical company, became the only company in the global market to have Plante Research and Development Centre, as a facility to manufacture bio-modified resin at the commercial level.

Some of the bio-based epoxies which are being approved for commercial use or currently under approval process in the market include epoxidized cardanols, linseed oil, liquid natural rubber, Terpene-maleic ester epoxy, Furan diepoxy of 2,5-bis(hydroxymethyl)-furan [BHMF], and Diglycidyl ethers of isosorbide [DGEI]. Bio-based epoxies are mostly mixed with natural, fillers, and fibers to improve their useful properties. For instance, these are blended with glass fibers to enhance their mechanical properties driving the market growth.

Industry Dynamics

Growth Drivers

Strong government response across the globe, to contain carbon emissions and positive sentiments towards the environmental problems, driving the market demand for the bio-based epoxy resins across end-use industries. Ecofriendly nature, biodegradability, and low production cost enables manufacturers to focus on renewable sources as raw material, which includes starch and other plant oils.

In line with this, in January 2020, the UK-based manufacturer of specialty polymers and other chemicals, Bitrez Ltd. introduced a new class of bio-based resins “Poly-furfuryl alcohol” for the composite market. It is derived from the biomass of crop waste, having similar characteristics as of phenolic resins, but counts low in carbon emissions. These resins were REACH (registration, evaluation, authorization, and restriction of chemicals) compliant.

Know more about this report: request for sample pages

Moreover, several end-use industries in the market such as coatings, construction, adhesives, and electronics strongly focus on green composites, as their corporate social responsibility, as a pledge to become a carbon-neutral company. Concerned industries carry out efforts to reduce the use of toxic and environment polluting materials.

Innovations in material science enable new formulations to enhance the mechanical properties of these bio-degradable resins. Manufacturers develop naturally derived epoxies from natural feedstocks such as plant, canola, and soyabean oil. There is increasing use of new raw materials in the market such as rosin-based, epoxidized rubber, and isosorbide based to have new formulations to improve its properties. Manufacturers in the market are focusing on innovative functionalities such as reparability, re-processing power, and recycle-ness driving the demand for bio-based epoxy resin.

How do the restrictions on bisphenol use in the European Union impact the Europe bio-based epoxy resins market?

The European bio-based epoxy resins industry players are required to comply with stringent environmental regulations. They must focus on controlling the use of resins in food contact materials. The regulatory landscape across the region is emphasizing addressing concerns regarding health and the environment, especially related to BPA (bisphenol A). It also encourages the development of sustainable alternatives. The following table provides detailed information on the regulatory framework for bio-based epoxy resins in Europe.

|

Regulation |

Description |

Impact on Bio-Based Epoxy Resins |

|

REACH Regulation (EC) No 1907/2006 |

The regulation controls the registration, evaluation, authorization, and restriction processes of chemicals in the EU countries. |

Manufacturers are required to assess and manage the risks of chemicals, such as bio-based epoxy resins. They must ensure the chemicals do not adversely affect human health and the environment. |

|

Commission Regulation (EU) No 10/2011 |

It establishes rules for plastic articles and materials that can come into contact with food products. |

The regulation sets migration limits for substances, including BPA, in food contact materials. This boosts the development of BPA-free alternatives. |

|

Regulation (EU) 2024/3190 |

It bans the use of BPA and its salts in food contact materials. |

There is an increasing shift toward adopting bio-based epoxy resins that do not contain BPA. It promotes the use of safer materials in food packaging. |

|

ECOXY Project (CBE JU) |

This aims to develop repairable, recyclable, and reprocessable bio-based epoxy resins and fiber-reinforced composites. |

It supports innovation in bio-based epoxy resins, aligning with EU sustainability goals and providing safer alternatives to traditional epoxy resins. |

Regulations are ensuring safety, proper product identification, and environmental protection throughout the supply chain. Bio-based epoxy resin manufacturers focus on ensuring compliance with such regulations and norms. Safety Data Sheets (SDS) provide them with detailed information on chemical properties and safety measures. A declaration of conformity demonstrates that products comply with EU safety and environmental standards. There is a rising emphasis on developing sustainable chemicals and materials that can adhere to the Safe and Sustainable-by-Design (SSbD) framework. Hence, imposition of stringent laws favoring sustainable materials, rising consumer preference for eco-friendly products, are expected to boost the adoption of bio-based epoxy resins across Europe in the coming years.

Bio-based Epoxy Resins Market Report Scope

The market is primarily segmented on the basis of ingredient, application, and region.

|

By Ingredient |

By Application |

By Region |

|

|

|

Know more about this report: request for sample pages

Insight by Ingredient

Based on the ingredient, the global market is categorized into vegetable, glycerol, canola, hemp, soya bean oil, plant oils, and others. In 2024, the plant oils segment accounted for the largest share in the market. The negative impacts of fossil fuel as feedstock and innovations in green chemistry are the prominent segment factors, responsible for its growth. Moreover, an increase in bio-refineries across the globe is favoring its growth.

Soyabean oil as a feedstock is projected to exhibit the highest growth over the forecast period. The growth is attributed to its maximum production in the emerging economies. The players in the region have developed such resin systems, which will boost its growth in the coming years.

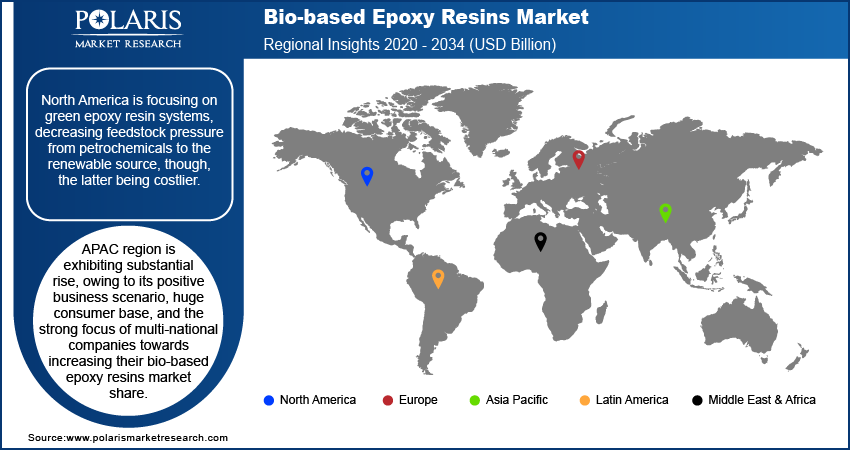

Geographic Overview

The bio-based epoxy resins market has been segmented based on regions, North America, Europe, Asia Pacific, Middle East & Africa, and Latin America. North America is focusing on green epoxy resin systems, decreasing feedstock pressure from petrochemicals to the renewable source, though, the latter being costlier. Key players in the organization are substituting their feedstock for natural plant-based oilseeds, owing to the environmental concerns of the petroleum-based products. The important factors driving the adoption of bio-based epoxy resins is the presence of harmful chemicals in petroleum-based resins, diminishing fossil fuels, and concerted efforts of several countries to reduce its dependence on non-renewable energy sources, and its applicability to several end-use industries. North American bio-based epoxy resins industry has several specialty chemicals company, within its territory, which robust supply chain network, are doing forward integration, by shifting feedstock from fossil fuels to naturally derived plant and vegetable oils.

APAC region is exhibiting substantial rise, owing to its positive business scenario, huge consumer base, and the strong focus of multi-national companies towards increasing their bio-based epoxy resins market share. The high production of automobiles including Evs is also leading the market growth. Moreover, the rising urbanization in the region, particulary in countries such as India and China are fueling the demand for bio-based epoxy resins. The growing shift toward carbon zero is also projected to drive the market growth in the region.

Competitive Insight

The bio-based epoxy resins market is increasing quickly as industries search for alternatives to petroleum-based materials. Growing demand in automotive, construction, and electronics has encouraged producers to refine resin quality while keeping a focus on sustainability. Larger companies are channeling resources into research to improve strength, durability, and thermal performance, while smaller firms look to capture attention with innovative, renewable solutions. Partnerships with raw material suppliers and regional expansion are common strategies to secure supply and strengthen market position. With the shift toward greener chemistry and stronger environmental commitments, competition is centered on balancing performance, affordability, and sustainability.

The prominent market players operating in the bio-based epoxy resin industry are Pond ApS, Kukdo Chemical, Bitrez Ltd, Sicomin Epoxy Systems, Huntsman Corporation, Entropy Resins (acquired by Gougeon Brothers Inc.), ALPAS, Chang Chun Group, Nagase ChemteX Corporation, LEUNAHarze GmbH, Spolchemie, Specific Polymers, ATL Composites, Stahl Holdings B.V., Change Climate, and Wessex Resins.

Bio-based Epoxy Resins Market Report Scope

|

Report Attributes |

Details |

|

Market Size in 2024 |

USD 2.09 Billion |

|

Market Size in 2025 |

USD 2.23 Billion |

|

Revenue Forecast by 2034 |

USD 4.06 Billion |

|

CAGR |

6.88% from 2025 to 2034 |

|

Base Year |

2024 |

|

Historical Data |

2020–2023 |

|

Forecast Period |

2025–2034 |

|

Quantitative Units |

Revenue in USD Billion and CAGR from 2025 to 2034 |

|

Report Coverage |

Revenue Forecast, Competitive Landscape, Growth Factors, and Industry Trends |

|

Segments Covered |

|

|

Regional Scope |

|

|

Competitive Landscape |

|

|

Report Format |

|

|

Customization |

Report customization as per your requirements with respect to countries, regions, and segmentation. |

FAQ's

• The global market size was valued at USD 2.09 billion in 2024 and is projected to grow to USD 4.06 billion by 2034.

• The global market is projected to register a CAGR of 6.88% during the forecast period.

• North America dominated the market in 2024

• A few of the key players in the market are Pond ApS, Kukdo Chemical, Bitrez Ltd, Sicomin Epoxy Systems, Huntsman Corporation, Entropy Resins (acquired by Gougeon Brothers Inc.), ALPAS, Chang Chun Group, Nagase ChemteX Corporation, LEUNAHarze GmbH, Spolchemie, Specific Polymers, ATL Composites, Stahl Holdings B.V., Change Climate, and Wessex Resins.

• The plant oils segment dominated the market revenue share in 2024.