Cartridge Filling System Market Share, Size, Trends, Industry Analysis Report

By Type; By Automation (Semi-automatic, Automatic); By End-User; By Region; Segment Forecast, 2024- 2032

- Published Date:May-2024

- Pages: 117

- Format: PDF

- Report ID: PM4895

- Base Year: 2023

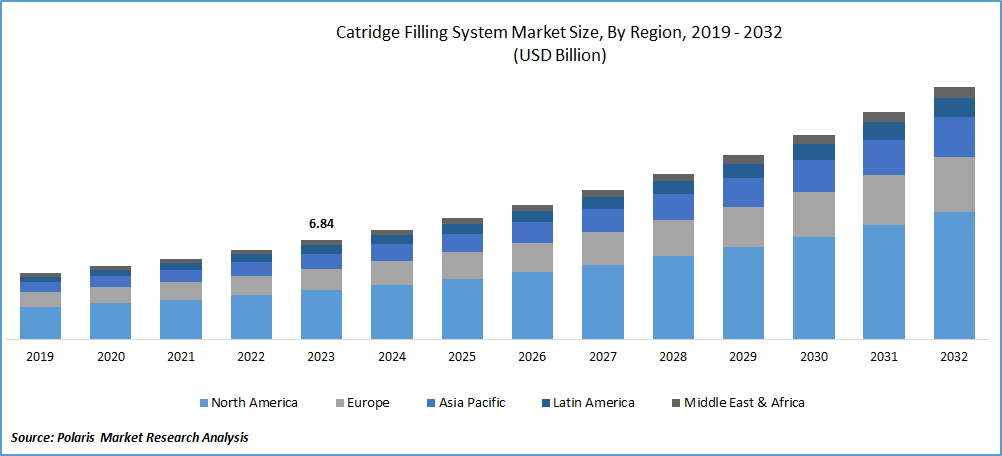

- Historical Data: 2019-2022

Report Outlook

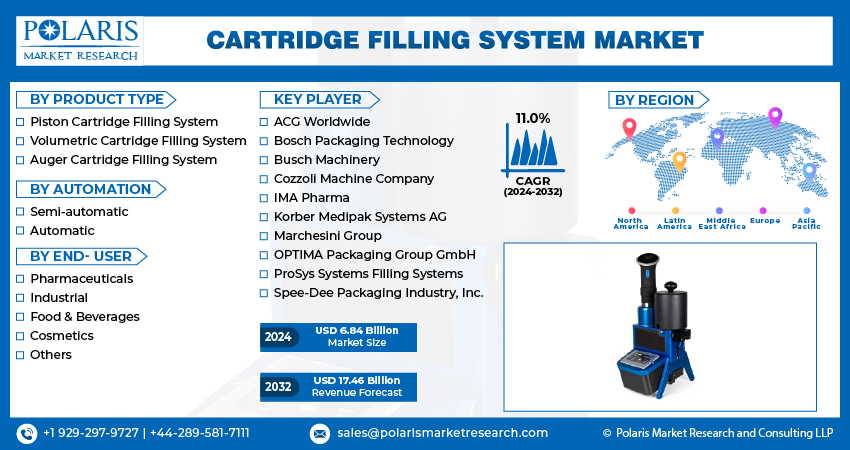

Cartridge Filling System Market size was valued at USD 6.84 billion in 2023. The market is anticipated to grow from USD 7.57 billion in 2024 to USD 17.46 billion by 2032, exhibiting the CAGR of 11.0% during the forecast period

Cartridge Filling System Market Overview

The rising adoption of cartridge filling systems by manufacturers and its wide applications in various sectors is leading the expansion of this market. The simplicity to use and high precision and accuracy during the filling process are driving the growth of this market. Cartridge filling system adoption is anticipated to be aided by their capacity to handle any liquid, even very viscous substances that can be put into tubes or cartridges, over the course of the forecast period. The technological developments, manufacturers may now incorporate cartridge filling systems into their setups, which streamlines the filling process and cuts down on labor-intensive steps and process times.

To Understand More About this Research:Request a Free Sample Report

For instance, in November 2022, the University of Oxford announced the launch of a brand-new world-class research facility to provide capabilities for next-generation advanced functional materials to help crucial societal, environmental, and industrial challenges.

Moreover, the integration of artificial intelligence in cartridge filling systems have enabled combining AI with sensors and intelligent quality monitoring systems. This promotes human resource training in both AI techniques and specialized techniques in filling machinery. Maintaining and building a common database for businesses, reducing the burden of data collection for each company along with specific product type leads to its flexible application of AI in automatic filling technology which will gradually enhance in the future.

However, during Covid-19 has led to increased demand for cartridge filling systems to produce bulk batches and reduce the manufacturing to market time and cost. Supply chain were disrupted giving rise to reduced manufacturing processes but since then the focus has been shifted to adoption of new solutions like remote cartridge filling systems which manages the production without human interaction providing the standard quality along with compliance with safety.

Cartridge Filling System Market Dynamics

Market Drivers

Rising Technological Advancements

The incorporation of cutting-edge technology like automation and robotics is one of the main trends in the market for cartridge filling machines. Manufacturers are able to increase filling process efficiency overall, decrease human error, and increase production as a result. Minimal changeover times are supported by fewer size parts, ensuring high-speed operations. Technology integrated cartridge filling systems are flexible, whether it be for small or big production batches with precise accuracy and effective results. Various filling volumes and technologies are adapting to evolving manufacturing needs required for meeting the rising consumer demands.

Customization in Cartridge Filling Systems

Cartridge filling systems can easily be customized allowing manufacturers to adjust the rate and flow of manufacturing production according to the requirements. These ensure no misuse or overuse of the product available by abiding to compliance leading to cost savings. The cartridge filling systems can be adjusted according to specific formulations, container sizes and production volume. These can be seamlessly integrated with the existing production line like conveyor belts, packaging systems, labelling machines.

Market Restraints

High Initial Investment Costs

The high initial investment costs and less awareness about the advanced technology integration is a major restraining factor. Its maintenance proves to be more expensive than the initial cost required for setting up cartridge filling systems. Moreover, advanced technology along with customization requirements makes it high-cost investment for manufacturers. The workforce needs to be trained and educated about the utilization of tech efficient cartridge filling systems which further requires additional investments. The components and parts used in the assembly of the systems are in demand and hence the prices keep rising leading to high-cost investments.

Report Segmentation

The market is primarily segmented based on product type, capacity, automation, end-user, and region.

|

By Product type |

By Automation |

By End- User |

By Region |

|

|

|

|

To Understand the Scope of this Report:Speak to Analyst

Cartridge Filling System Market Segmental Analysis

By Product Type Analysis

- Volumetric filling systems have shown significant growth over the forecast period as they are made to precisely and effectively fill containers with liquids. These systems transport product from a central filling tank and distribute it into the container using a set of pre-dosing pistons. These systems are perfect for handling liquids with different densities since the pistons are calibrated to guarantee exact filling volumes. Volumetric filling methods are very adaptable; as various fillers may be used to manage a variety of liquid kinds. These systems are perfect for a range of applications in the food and beverage sector as well as other industries since they are dependable, accurate, and simple to use.

- Piston cartridge filling systems are integrated filling system that makes use of a plunger piston. To draw in or release ink, the plunger is moved up and down by a movable end cap on the barrel. The mechanism cap often operates by twisting; however, it occasionally operates on a push/pull basis. By rotating the piston knob at the end of the barrel, an object with a built-in reservoir may be filled by dipping it straight into an ink bottle. Piston-fillers frequently hold more ink.

By Automation Analysis

- The automated cartridge filling systems have shown remarkable growth owing to their use of hard plastic cartridges which are made for the high-speed, completely automated packing of sealants, adhesives, silicones, and caulks. Sorting and feeding cartridge bodies, precise filling, sorting, feeding, and inserting pistons, and inkjet tagging are all done with optimal efficiency and without the need for user intervention. These automated cartridge filling systems ensures automatic cartridge filling ensuring consistency and quality by increasing productivity and scaling capacities.

- Semi- automated cartridge filling systems requires human operators in assisting in a number of filling process steps, including putting cartridges into the machine, starting filling cycles, and quality-controlling completed cartridge inspections. demands human operators to actively participate in a number of filling process steps, including inserting cartridges into the machine, starting filling cycles, and quality-control inspection of filled cartridges. demands human operators to actively engage in a number of filling process steps, including inserting cartridges into the machine, starting filling cycles, and quality-control inspection of filled cartridges.

By End-User Analysis

- Pharmaceutical sector has substantially shown rapid growth owing to their wide applications in sectors such as diabetes, dentistry, and emergency care, as they are appropriate for both biologic and non-biologic drugs. They provide patients more independence by offering a greater range of requirements and medication administration options, such pens, auto-injectors, and consumables by reducing the risk of contamination ensuring and maintaining pharmaceutical standards.

- Cartridge filling systems are used in food and beverages owing to their application in high volume production maintain industry-leading settling time. Its integrated functionality allows producers to reduce tooling and station redundancy and achieve high-performance in the least amount of area. Additionally, the platform provides a range of design choices to address your particular space-related equipment issues for food processing. This also ensures energy efficiency and real time production data monitoring especially during the filling of liquid, semi-liquid, brewed substances.

Cartridge Filling System Market Regional Insights

The North America Region has Shown Fastest Growth Over the Forecast Period in the Global Market

North American region is set to grow rapidly over the forecast period owing to rapid technological advancements and integration of technology in cartridge filling systems as these are adopted by various manufactures all over the region. Its automation efficiency, precise volume filling, energy efficiency, cost saving and less labour intensive features are driving the growth of this market. These are widely used in pharmaceutical sector for capsule filling, auto injectors, liquid substance precise fillings along with complying with the quality of standard.

Growth prospects are available in the Asia-Pacific area since the industrial and pharmaceutical industries are growing. The market gains when emerging nations in the Asia-Pacific area embrace innovative manufacturing techniques.

Competitive Landscape

The Cartridge Filling System Market is fragmented and is anticipated to witness competition due to several players' presence. Major service providers in the market are constantly upgrading their technologies and ensuring standardized regulations to ensure compliance and to stay ahead of the competition. These players focus on partnership, product upgrades, introducing new product ranges by integration of technology and collaboration to gain a competitive edge over others and capture a significant market share.

Some of the major players operating in the global market include:

- ACG Worldwide

- Bosch Packaging Technology

- Busch Machinery

- Cozzoli Machine Company

- IMA Pharma

- Korber Medipak Systems AG

- Marchesini Group

- OPTIMA Packaging Group GmbH

- ProSys Systems Filling Systems

- Spee-Dee Packaging Industry, Inc.

Recent Developments

- In April 2024, Kindeva Drug Delivery installs the first Syntegon Versynta microBatch Filling System in North America, expanding its range of aseptic fill-finish CDMO (contract development and manufacturing) capabilities to meet the recent global pharmaceutical standards and trends.

- In February 2024, INCOG BioPharma Services Expands Syringe/Cartridge Capacity by 100 Million Units. It will supplement the business's current multipurpose filling line, increasing its annual filling capacity to 140 million units.

Report Coverage

The Cartridge Filling System market report emphasizes on key regions across the globe to provide better understanding of the product to the users. Also, the report provides market insights into recent developments, trends and analyzes the technologies that are gaining traction around the globe. Furthermore, the report covers in-depth qualitative analysis pertaining to various paradigm shifts associated with the transformation of these solutions.

The report provides detailed analysis of the market while focusing on various key aspects such as competitive analysis, product type, automation, end-users, and their futuristic growth opportunities.

Cartridge Filling System Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2024 |

USD 6.84 billion |

|

Revenue forecast in 2032 |

USD 17.46 billion |

|

CAGR |

11.0% from 2024 – 2032 |

|

Base year |

2023 |

|

Historical data |

2019 – 2022 |

|

Forecast period |

2024 – 2032 |

|

Quantitative units |

Revenue in USD billion and CAGR from 2024 to 2032 |

|

Segments covered |

By Product Type, By Automation, By End-User, By Region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

|

Customization |

Report customization as per your requirements with respect to countries, region, and segmentation. |

FAQ's

Cartridge Filling System Market Size Worth $ 17.46 Billion By 2032

The top market players in Cartridge Filling System Market Korber Medipak Systems AG, Marchesini Group, OPTIMA Packaging Group GmbH

North American is region contribute notably towards the Cartridge Filling System Market

Cartridge Filling System Market exhibiting the CAGR of 11.0% during the forecast period.

Cartridge Filling System Market report covering key segments are product type, capacity, automation, end-user, and region.