Industrial Evaporator Market Share, Size, Trends, Industry Analysis Report

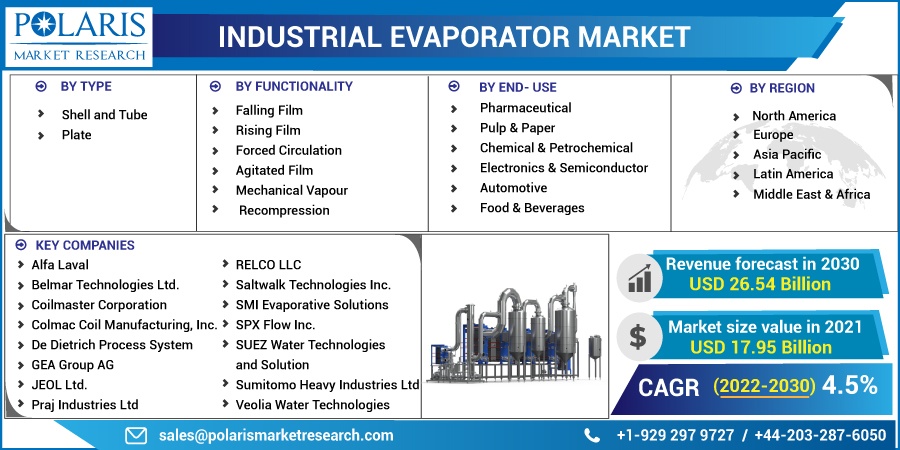

By Type; By End-Use (Automotive, Pulp & Paper, Food & Beverages, Pharmaceutical, Electronic & Semiconductors, Chemical & Petrochemical); By Functionality; By Region; Segment Forecast, 2022 - 2030

- Published Date:Sep-2022

- Pages: 112

- Format: PDF

- Report ID: PM2560

- Base Year: 2021

- Historical Data: 2018-2020

Report Outlook

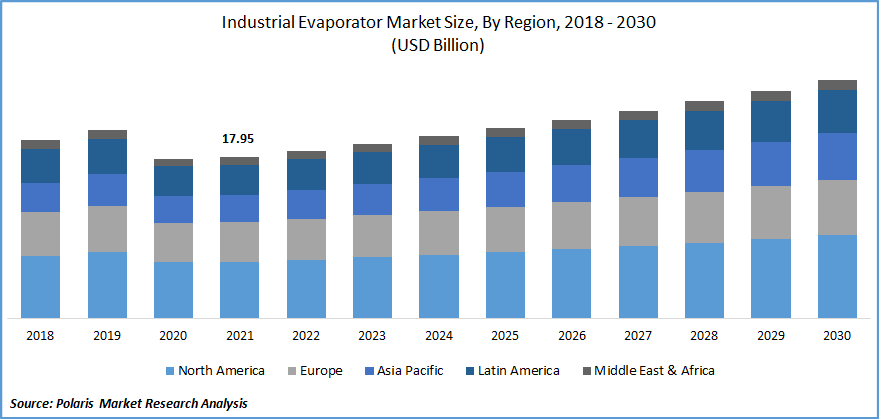

The industrial evaporator market was valued at USD 17.95 billion in 2021 and is expected to grow at a CAGR of 4.5% during the forecast period. Industrial evaporators are widely used in the food & beverage industry owing to high use of water for processing applications. In addition, efficient evaporation of water to improve the shelf life of the food products is expected to drive its demand in the sector.

Know more about this report: Request for sample pages

The outbreak of the COVID-19 pandemic has significantly impacted the growth of the industrial evaporators market worldwide. Stringent lockdowns highly influenced the supply chain and declined demand for non-essentials, which led to decline in the demand for industrial evaporators in several industries. Additionally, shutdown of production facilities due to curb the spreading of Covid-19 infections also had a negative impact on the market growth.

Know more about this report: Request for sample pages

Know more about this report: Request for sample pages

Industry Dynamics

Growth Drivers

The global industrial evaporator market is driven by the increase in demand for changing trends, increased population, rising disposable income, and product development. The increase in industrialization in Asian countries such as Japan, China, and India have designed opportunities for the growth of the industrial evaporator market.

The initial reason for the increasing demand for industrial evaporators was growing adoption of Zero Liquid Discharge (ZLD) technology. These products are also used for desalinating sea water or brackish water using a multiple effect distillation technique, which is cost-effective.

Due to growing awareness about increased usage of water treatment applications, the market has grown for industrial evaporators. The rapidly increasing population has led to increasing consumption of water and dairy products which is also influencing the growth of industrial evaporators.

Additionally, some advancement in the basic design of the system to reduce scaling is expected for fuel growth. The growing adoption of electron beam type in the semiconductor industry for deposition processes and mechanical vapor recompression type in oil sand industries have also driven the growth of the market.

Report Segmentation

The market is primarily segmented based on type, functionality, end-use, and region.

|

By Type |

By Functionality |

By End- Use |

By Region |

|

|

|

|

Know more about this report: Request for sample pages

Plate evaporator accounted for the largest market share in 2021

On the basis of type, the industrial evaporator market is categorized into shell and tube and plate. Plate segment accounted for the largest revenue share in 2021 as they are highly efficient for energy saving, have expandable capacity, have the highest heat transfer coefficient, have higher product concentration, and are easier to clean.

Plate type have many advantages compared to shell and tube type which make them ideal for many operations. The plate systems are compact in size and low weight, so it acquires less space as compared to shell and tube type, also the installation cost of plate type is lower as compared to its counterpart. Due to the stainless steel surface packed within the plate, in plate type, it is easily cleanable.

The demand for the plate evaporator market is driven by the increased application in food & beverages, pharmaceuticals, chemical & petrochemical, electronics, automotive, and others. Amongst the industrial segment, the food & beverage industry widely use plate technology as they are used for concentration of juice, beverage, milk, starch, coffee, vegetable pastes & concentrate, sauces, sugar, and edible oil.

Mechanical vapor recompression is expected to hold the significant revenue share

On the basis of functionality, the market has been segmented into falling film, rising film, forced circulation, agitated film, and mechanical vapor recompression. The mechanical vapor recompression segment accounted for the largest market share in 2021. It is also estimated to be the fastest-growing segment during the forecast period.

The application for industrial evaporators is growing due to increased demand from food & beverages, chemical & pharmaceuticals, automotive, electronics, and other industries. Mechanical vapor recompression helps to compress water vapor creating a rise in temperature and pressure. The main advantage that drives the mechanical vapor recompression evaporator is low energy consumption. Also, it reduces the load on the cooling tower, simplifies the evaporation process, and has a higher performance co-efficient which makes it more efficient.

The demand for mechanical vapor recompression is driven by the applications in the treatment of leachates, degreasing water, dissolved oil and hydrocarbons in contaminated water, salt water and brine, demolding and oil emulsion, and others.

Food & Beverage is expected to grow at the highest rate during the forecast period

Based on end-use, the market has been segmented into pharmaceutical, pulp & paper, automotive, food & beverages, chemical & petrochemical, electronic & semiconductors, and others. The food & beverage segment accounted for the largest market share in 2021. It is also estimated to be the fastest-growing segment during the forecast period.

Industrial evaporators in the food and beverage industry are used for moisture removal, which helps to increase total solids in food, reduce bulk density, and facilitate transportation. Also, the evaporators help to pre-concentrate food, to change the color of the food, and to reduce the water content of the liquid products, which helps increase the shelf life of the products such as sauces, jams, juices, and others. Additionally, they help to reduce the cost related to storage space required for liquid that needs refrigeration.

The specific application in the food industry where industrial evaporators are mostly used is protein manufacturing and dairy industries. Nowadays customers prefer packaged food, concentrated juices, and ready to make foods which have increased the demand for evaporators. The growing popularity of flavored milk is also one of the factors driving market growth.

Asia Pacific is projected to grow at the highest growth rate during the forecast period

The market in Asia Pacific is expected to increase at the fastest rate during the forecast period. The growing demands in the region including China, India, and Japan have created opportunities for industries including pharmaceuticals, automotive, chemicals, petrochemicals, food & beverages, and electronics, driving the demand over the forecast period.

The changing trends, increased population, and rising disposable incomes have raised the product development in this region, resulting expansion of the industrial evaporator market. Rapid industrialization and urbanization are creating the need for efficient water treatment facilities, which is one of the major factors driving the market demand in the region.

Competitive Insight

Some of the major players operating in the global market include Alfa Laval, Belmar Technologies Ltd., Coilmaster Corporation, Colmac Coil Manufacturing, Inc., De Dietrich Process System, GEA Group AG, JEOL Ltd., Praj Industries Ltd, RELCO LLC, Saltwalk Technologies Inc., SMI Evaporative Solutions, SPX Flow Inc., SUEZ Water Technologies and Solution, Sumitomo Heavy Industries Ltd, Veolia Water Technologies.

Recent Developments

In 2019, Veolia Water Technologies Inc., was awarded a contract by Smurfit Kappa to increase liquor treatment capacity and optimize the efficiency of recovery boiler operation by installation of an HPD concentration and evaporation system. In addition, recently in 2022, Lone Star completed its acquisition with SPX Flow.

Industrial Evaporators Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2021 |

USD 17.95 billion |

|

Revenue forecast in 2030 |

USD 26.54 billion |

|

CAGR |

4.5% from 2022 - 2030 |

|

Base year |

2021 |

|

Historical data |

2018 - 2020 |

|

Forecast period |

2022 - 2030 |

|

Quantitative units |

Revenue in USD billion and CAGR from 2022 to 2030 |

|

Segments covered |

By Type, By Functionality, By End-Use, By Region |

|

Regional scope |

North America, Europe, Asia Pacific, Latin America; Middle East & Africa |

|

Key companies |

Alfa Laval, Belmar Technologies Ltd., Coilmaster Corporation, Colmac Coil Manufacturing, Inc., De Dietrich Process System, GEA Group AG, JEOL Ltd., Praj Industries Ltd, RELCO LLC, Saltwalk Technologies Inc., SMI Evaporative Solutions, SPX Flow Inc., SUEZ Water Technologies and Solution, Sumitomo Heavy Industries Ltd, Veolia Water Technologies. |