Industrial RF Heating Equipment Market Size, Share, Trends, Industry Analysis Report

By Type (Continuous Type, Batch Type), By Application, By Region – Market Forecast, 2025–2034

- Published Date:Sep-2025

- Pages: 125

- Format: PDF

- Report ID: PM6408

- Base Year: 2024

- Historical Data: 2020-2023

Overview

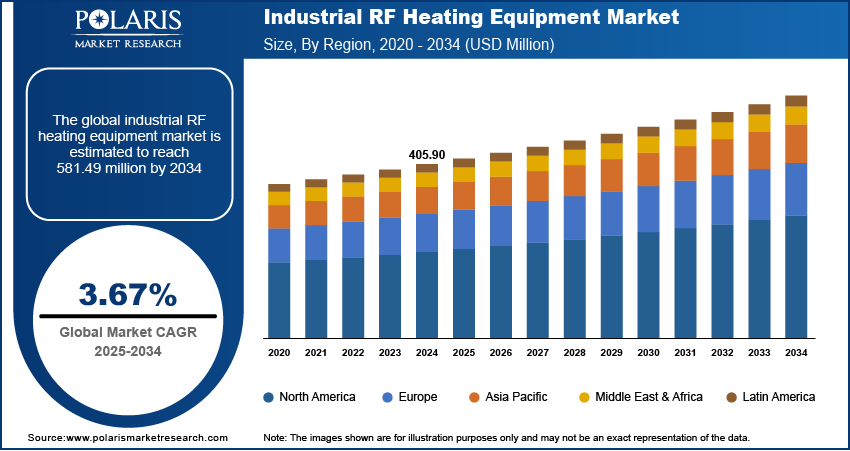

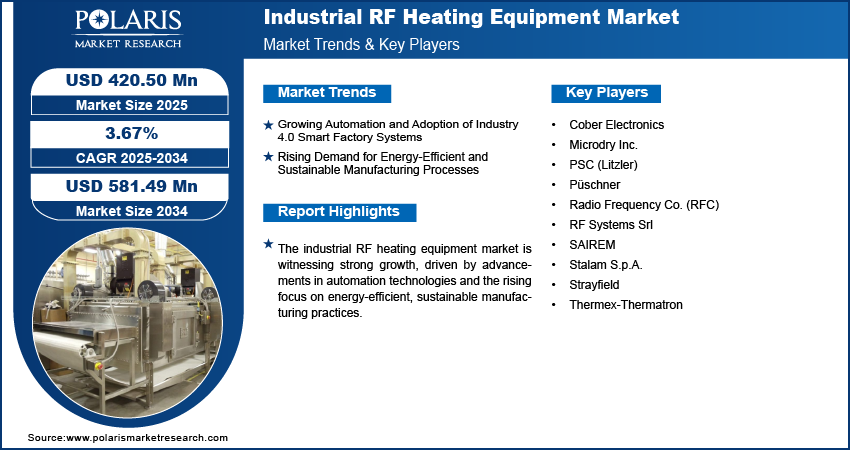

The global industrial RF heating equipment market size was valued at USD 405.90 million in 2024, growing at a CAGR of 3.67% from 2025 to 2034. Key factors driving demand include advancements in RF solid-state amplifier technology, offering improved accuracy and controllability, regulatory and government support for energy-efficient and clean technologies, automation and adoption of Industry 4.0, and demand for energy-efficient and sustainable manufacturing processes.

Key Insights

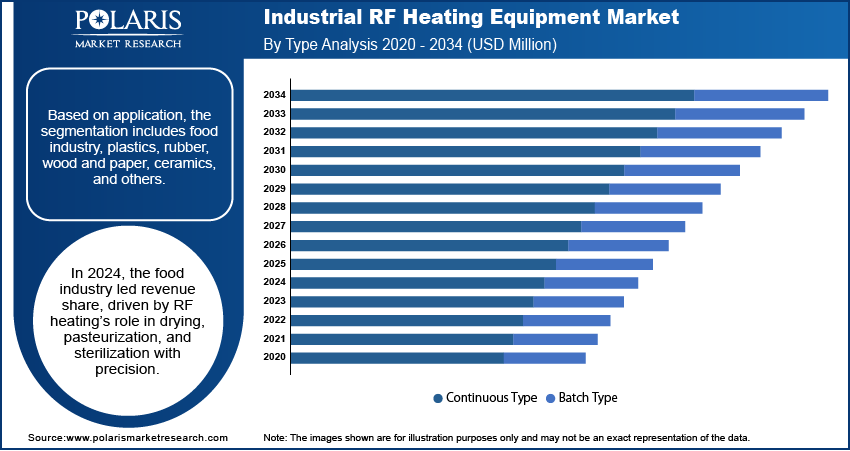

- The continuous systems segment is poised for significant growth during the forecast period, as it provides uniform, high-efficiency heating ideal for high-volume production lines.

- The food industry led the market revenue share in 2024, due to its extensive use of RF heating for precise, quality-preserving processes such as drying and pasteurization.

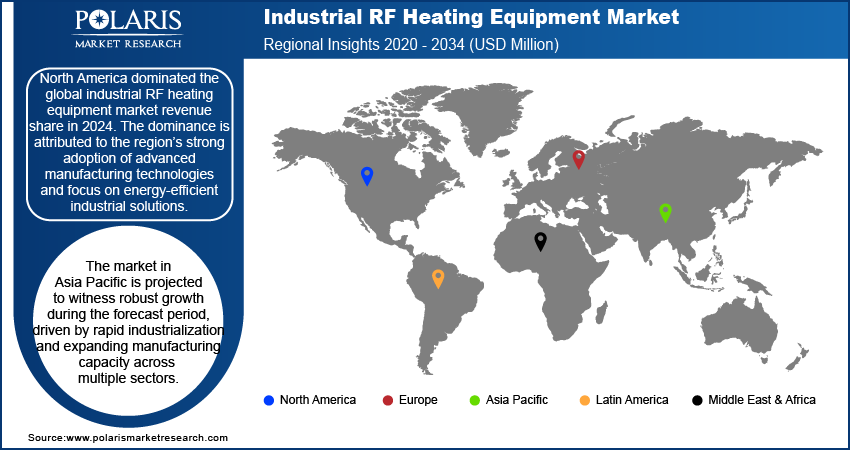

- North America held the largest global market share in 2024, fueled by its widespread adoption of advanced, energy-efficient manufacturing technologies.

- The U.S. dominated the North America landscape in 2024, due to its strong focus on advanced manufacturing and the rapid implementation of Industry 4.0 systems.

- The Asia Pacific market is expected to witness robust growth during the forecast period, by rapid industrialization and the expansion of manufacturing capabilities in the region.

- India's market is growing due to accelerated industrialization and the increasing integration of modern technologies to boost production efficiency.

Industry Dynamics

- The shift toward Industry 4.0 and automated smart factories is accelerating demand for the precise, controllable heating provided by RF equipment.

- A rising focus on sustainable manufacturing is driving adoption, as RF technology reduces energy consumption and waste in industrial processes.

- High initial capital investments and system complexity can be a significant barrier to adoption, especially for small and medium-sized manufacturers.

- A global push for energy-efficient, sustainable manufacturing creates a major growth opportunity, as RF heating drastically reduces energy use and waste compared to conventional methods.

Market Statistics

- 2024 Market Size: USD 405.90 million

- 2034 Projected Market Size: USD 581.49 million

- CAGR (2025–2034): 3.67%

- North America: Largest market in 2024

AI Impact on Industrial RF Heating Equipment Market

- AI algorithms analyze real-time data to optimize power consumption in RF heating systems, significantly reducing energy waste and operational costs while maintaining consistent performance across diverse industrial applications.

- AI enables highly accurate temperature and frequency control in RF heating, ensuring uniform heating, minimizing defects, and improving the overall quality and consistency of processed materials or components.

- Machine learning models predict equipment failures by monitoring performance patterns, allowing timely maintenance, minimizing unplanned downtime, extending equipment lifespan, and reducing repair costs across manufacturing environments.

- AI facilitates advanced automation of RF heating processes, enabling scalable production with minimal human intervention, improving throughput, and supporting complex industrial requirements with adaptive, intelligent control systems.

Industrial RF heating equipment, defined as systems that utilize radio frequency energy to generate heat for industrial processes, is gaining traction due to its precision, efficiency, and suitability for a wide range of applications. The growth of this market is fueled by the advancement in RF solid-state amplifier technology, which provides enhanced accuracy, stability, and controllability compared to traditional vacuum tube systems. These improvements allow industries to achieve consistent heating performance, minimize process variability, and optimize energy consumption. Solid-state amplifiers expand the potential use of RF heating in applications such as drying, curing, and material processing by enabling more precise control over temperature and power distribution, thereby strengthening its adoption across multiple industries.

Regulatory and government support for energy-efficient and clean technologies would create market growth opportunities during the forecast period. A growing focus on sustainable manufacturing practices and reduced environmental impact has pushed industries to adopt heating solutions that minimize carbon emissions and improve energy utilization. In July 2025, India's Ministry of Power launched the ADEETIE scheme with a USD 20 million budget, offering a 3–5% interest subsidy on loans to MSMEs for adopting energy-efficient technologies and projects. RF heating systems align with these goals, as they provide faster processing times with lower energy losses compared to conventional heating methods. Supportive policies and incentives further encourage industries to transition toward RF-based technologies, positioning them as a viable alternative to traditional energy-intensive heating systems. This regulatory push promotes innovation and also ensures that RF heating continues to align with global sustainability objectives.

Drivers & Opportunities

Growing Automation and Adoption of Industry 4.0 Smart Factory Systems: The growing automation and adoption of Industry 4.0 smart factory systems are boosting the adoption of this equipment, as these technologies demand precise, controllable, and efficient heating solutions. In December 2024, India’s Ministry of Heavy Industries established four SAMARTH centres to train the workforce, including MSMEs, on Industry 4.0 technologies under a scheme to enhance competitiveness in the capital goods sector. RF heating equipment integrates seamlessly with automated production lines, offering real-time monitoring, digital control, and adaptability to diverse industrial processes. The ability to provide uniform and consistent heating supports the objectives of smart factories, where efficiency, accuracy, and reduced downtime are paramount. This alignment with Industry 4.0 enhances operational efficiency and also positions RF heating as a critical enabler of advanced manufacturing environments.

Rising Demand for Energy-Efficient and Sustainable Manufacturing Processes: Rising demand for energy-efficient and sustainable manufacturing processes further strengthens the market growth of industrial RF heating equipment. Manufacturers across industries are increasingly prioritizing solutions that reduce energy consumption, minimize waste, and support eco-friendly operations. RF heating addresses these needs by delivering targeted energy application with minimal losses, enabling faster processing with lower environmental impact compared to conventional methods. RF heating technologies emerge as essential tools that balance performance with environmental responsibility as sustainability becomes central to industrial strategies, making them highly attractive in the transition toward greener manufacturing.

Segmental Insights

Type Analysis

Based on type, the segmentation includes continuous type and batch type. The continuous type segment is expected to witness substantial growth during the forecast period, owing to its ability to deliver consistent heating with high efficiency in large-scale production environments. Continuous systems are particularly suited for industries that demand uninterrupted operations, as they ensure uniform energy distribution and reduced processing time. Their integration with automated systems further enhances productivity and minimizes operational downtime, making them a preferred choice for modern manufacturing setups. This advantage positions continuous RF heating equipment as an important driver of industrial adoption in high-output sectors.

Application Analysis

In terms of application, the segmentation includes food industry, plastics, rubber, wood and paper, ceramics, and others. The food industry segment dominated the revenue share in 2024 due to its strong reliance on RF heating for applications such as drying, pasteurization, and sterilization, where precise temperature control and preservation of product quality are critical. RF heating offers the advantage of rapid, uniform heating, which helps maintain nutritional value and extends shelf life while improving processing efficiency. Additionally, the growing demand for processed and packaged food products has further strengthened the adoption of RF heating solutions, establishing the food sector as a primary contributor to market growth.

Regional Analysis

The North America industrial RF heating equipment market accounted for the largest global revenue share in 2024. This dominance is attributed to the region’s strong adoption of advanced manufacturing technologies and focus on energy-efficient industrial solutions. Industries across the region are increasingly incorporating RF heating systems to enhance operational precision and reduce energy consumption in line with sustainability goals. In October 2024, Strayfield launched RF drying solutions in the USA for ceramic fiber boards, shapes, and blankets. The technology ensures uniform drying, reduces energy use, shortens processing times, and enhances product quality for industrial applications. Furthermore, the presence of a developed industrial base and rapid integration of automation technologies supports the widespread deployment of RF heating solutions, reinforcing North America’s leading position in the global market.

U.S. Industrial RF Heating Equipment Market Insights

The U.S. held a significant market share in North America industrial RF heating equipment landscape in 2024 due to its strong focus on advanced manufacturing practices and rapid integration of smart factory systems. The country’s focus on automation, precision, and energy efficiency has encouraged industries to adopt RF heating solutions for consistent and controllable processes. Additionally, a developed industrial ecosystem with a high demand for food processing, plastics, and material treatment applications further strengthens the U.S. position in the regional market.

Asia Pacific Industrial RF Heating Equipment Market Trends

The market in Asia Pacific is projected to witness robust growth during the forecast period, driven by rapid industrialization and expanding manufacturing capacity across multiple sectors. According to a 2024 UN Industrial Development Organization report, the manufacturing output of Asia and Oceania, excluding China, grew at a rate of 1.6%. Growing focus on cost-effective production methods and the adoption of advanced technologies for efficiency improvements are further accelerating the growth of RF heating solutions. The region's evolving industrial landscape, driven by rising demand for processed foods, plastics, and other finished products, enables a conducive growth environment. This expanding adoption highlights Asia Pacific as one of the fastest-growing regions in the RF heating equipment market.

India Industrial RF Heating Equipment Market Overview

The market in India is expanding due to rapid industrialization and increasing adoption of modern production technologies aimed at improving efficiency. RF heating systems are being increasingly utilized for their ability to enhance output while conserving energy, particularly in the processed food, plastics, and other consumer-driven industries. Furthermore, growing awareness around sustainable manufacturing practices is pushing industries in India to explore RF-based solutions as a viable alternative to conventional heating methods.

Europe Industrial RF Heating Equipment Market Analysis

The industrial RF heating equipment industry in Europe is projected to hold a substantial share by 2034, supported by the region’s strong focus on sustainable and energy-efficient technologies. European industries are actively aiming for solutions that align with strict environmental standards while improving manufacturing efficiency, making RF heating systems an attractive option. According to 2024 data from the UN Industrial Development Organization, European manufacturing production grew by a marginal increase of 0.2% in the second quarter of the year. The region’s established industrial base, combined with ongoing investments in modern production technologies, creates a conducive environment for adoption. This focus on balancing technological advancement with environmental responsibility positions Europe as an important contributor to the global RF heating equipment market over the long term.

UK Industrial RF Heating Equipment Market Outlook

The UK market growth is driven by the country’s strong focus on sustainability and compliance with strict energy efficiency standards in industrial operations. Industries are adopting RF heating solutions to reduce energy consumption, optimize production processes, and align with environmental goals. Additionally, the UK’s well-established industrial base, with ongoing modernization initiatives, supports the growing deployment of advanced RF heating equipment across multiple application areas.

Key Players & Competitive Analysis

The industrial RF heating equipment sector is characterized by intense competition among established players such as Püschner, Stalam, and SAIREM, who leverage technological advancement and strategic investments to strengthen their regional footprint and product offerings. Competitive intelligence and strategy reveal that vendors are targeting both developed markets, where demand for efficiency is high, and emerging markets, which present expansion opportunities due to growing industrialization. Key strategic developments include a shift toward solid-state generators and IoT-enabled systems, driven by industry trends toward automation and sustainability. For small and medium-sized businesses, navigating supply chain disruptions and economic and geopolitical shifts remains a challenge. Expert's insight suggests that future growth projections hinge on innovating for sustainable value chains and leveraging latent demand and opportunities in sectors like advanced materials and food processing. Vendor strategies are increasingly focused on future development strategies that integrate energy-efficient solutions to capitalize on this revenue opportunity.

A few major companies operating in the industrial RF heating equipment market include Cober Electronics, Microdry Inc., PSC (Litzler), Püschner, Radio Frequency Co. (RFC), RF Systems Srl, SAIREM, Stalam S.p.A., Strayfield, and Thermex-Thermatron.

Key Players

- Cober Electronics

- Microdry Inc.

- PSC (Litzler)

- Püschner

- Radio Frequency Co. (RFC)

- RF Systems Srl

- SAIREM

- Stalam S.p.A.

- Strayfield

- Thermex-Thermatron

Industrial RF Heating Equipment Industry Developments

- September 2025: Stalam and its U.S. distributor launched advanced RF systems for industrial baking. WAVEDRY+ prevents cracking and ensures uniform drying. WAVEBAKE+ enables crustless bread via volumetric heating, ensuring precise control and minimal crust formation.

- September 2024: Radio Frequency Co. launched a non-contact RF dryer for medical/technical yarns. It uses radio waves to dry aqueous solutions at high speed, preventing solid migration and surface crusting without mechanical contact or excessive heat.

Industrial RF Heating Equipment Market Segmentation

By Type Outlook (Revenue, USD Million, 2020–2034)

- Continuous Type

- Batch Type

By Application Outlook (Revenue, USD Million, 2020–2034)

- Food Industry

- Plastics

- Rubber

- Wood and Paper

- Ceramics

- Others

By Regional Outlook (Revenue, USD Million, 2020–2034)

- North America

- U.S.

- Canada

- Europe

- Germany

- France

- UK

- Italy

- Spain

- Netherlands

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Malaysia

- South Korea

- Indonesia

- Australia

- Vietnam

- Rest of Asia Pacific

- Middle East & Africa

- Saudi Arabia

- UAE

- Israel

- South Africa

- Rest of Middle East & Africa

- Latin America

- Mexico

- Brazil

- Argentina

- Rest of Latin America

Industrial RF Heating Equipment Market Report Scope

|

Report Attributes |

Details |

|

Market Size in 2024 |

USD 405.90 Million |

|

Market Size in 2025 |

USD 420.50 Million |

|

Revenue Forecast by 2034 |

USD 581.49 Million |

|

CAGR |

3.67% from 2025 to 2034 |

|

Base Year |

2024 |

|

Historical Data |

2020–2023 |

|

Forecast Period |

2025–2034 |

|

Quantitative Units |

Revenue in USD Million and CAGR from 2025 to 2034 |

|

Report Coverage |

Revenue Forecast, Competitive Landscape, Growth Factors, and Industry Trends |

|

Segments Covered |

|

|

Regional Scope |

|

|

Competitive Landscape |

|

|

Report Format |

|

|

Customization |

Report customization as per your requirements with respect to countries, regions, and segmentation. |

FAQ's

The global market size was valued at USD 405.90 million in 2024 and is projected to grow to USD 581.49 million by 2034.

The global market is projected to register a CAGR of 3.67% during the forecast period.

North America dominated the market in 2024.

A few of the key players in the market are Cober Electronics, Microdry Inc., PSC (Litzler), Püschner, Radio Frequency Co. (RFC), RF Systems Srl, SAIREM, Stalam S.p.A., Strayfield, and Thermex-Thermatron.

The food industry dominated the revenue share in 2024.

The continuous type segment is expected to witness substantial growth during the forecast period