Modified Polypropylene Market Share, Size, Trends, Industry Analysis Report

By Type (Physical Modification, Chemical Modification); By Application; By Region, And Segment Forecasts, 2024 - 2032

- Published Date:Feb-2024

- Pages: 116

- Format: PDF

- Report ID: PM4578

- Base Year: 2023

- Historical Data: 2019 – 2022

Report Outlook

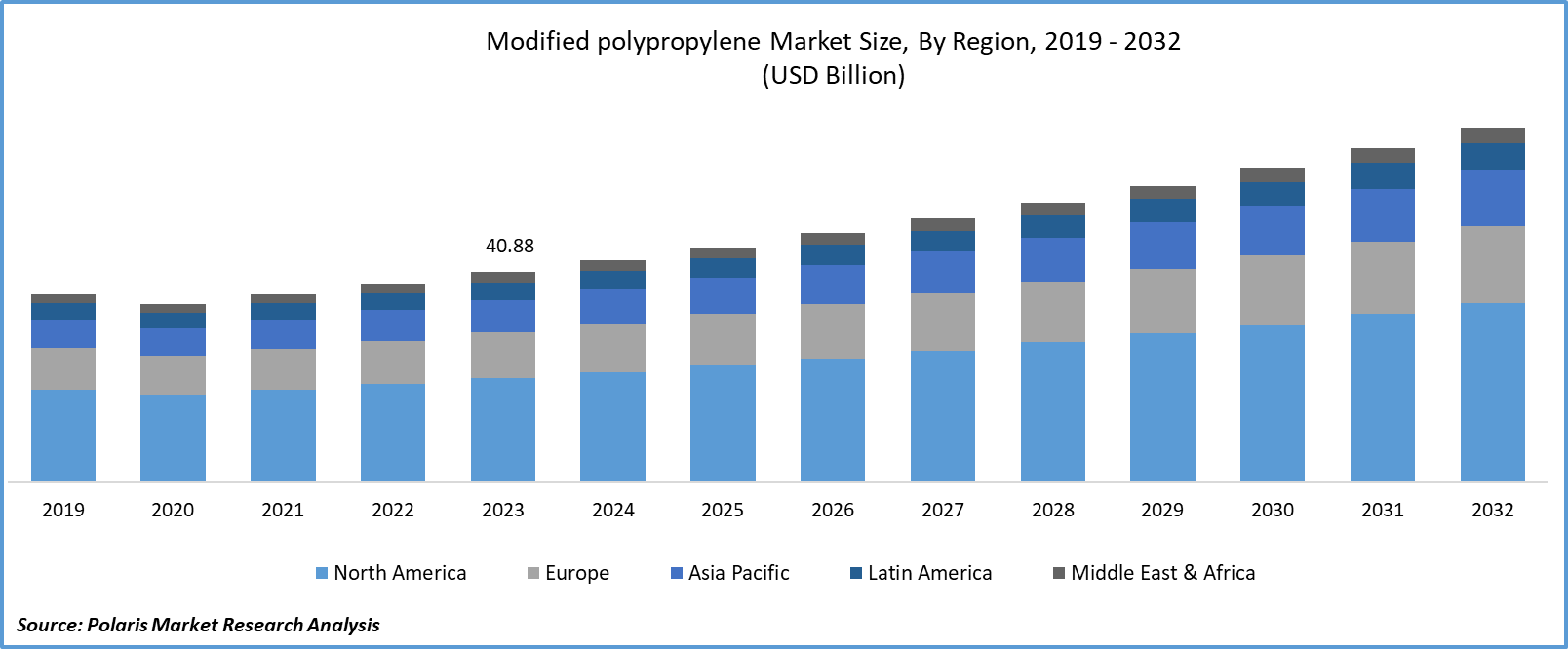

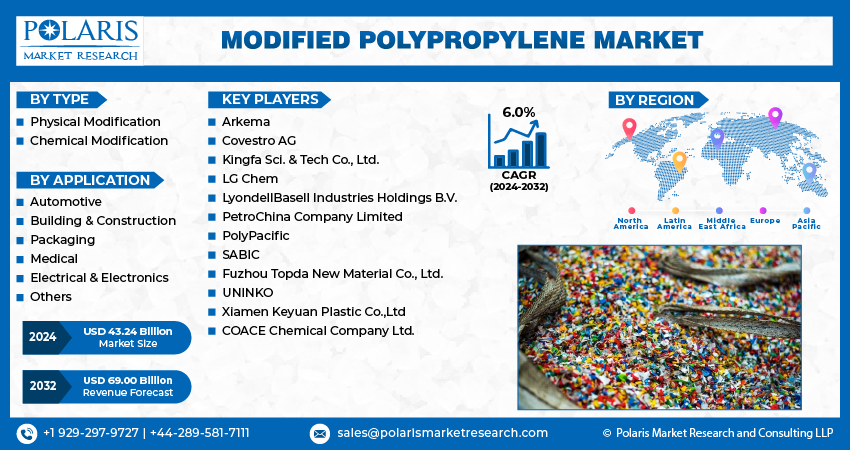

Global modified polypropylene market size was valued at USD 40.88 billion in 2023. The market is anticipated to grow from USD 43.24 billion in 2024 to USD 69.00 billion by 2032, exhibiting the CAGR of 6.0% during the forecast period.

Market Overview

The demand for the modified polypropylene market size & trends is credited to the application of modified polypropylene across diverse sectors, including automotive, electrical and electronics, packaging, medical, building, and construction. Within the automotive sector, technological progressions, increasing disposable incomes, and a shift in population preferences toward electric vehicles have fueled growth. Furthermore, the rising need for lightweight materials as substitutes for metals has driven the demand for modified polypropylene polymer across automotive, electrical, electronics, buildings, and construction.

The market for modified polypropylene has significant demand due to the presence of several key players, as well as a smaller number of medium and small regional players. Established companies like Borealis AG are prominent players in this market, leveraging their experience and expertise to develop modified polypropylene formulations that are well-suited for a wide range of applications. These established players often have significant resources, research and development capabilities, and global reach, which give them a competitive advantage over their competitors.

For instance, In October 2022, Borealis unveiled the Borstar Extension Technology, representing a significant advancement in performance-based polyolefins. This breakthrough technology expands the range of properties available for polypropylene (PP), leveraging the proven performance of Borstar and innovative single-site Borstar Nextension catalysts. This proprietary technology marks a groundbreaking step towards enhancing plastic circularity by streamlining the design for recycling.

To Understand More About this Research: Request a Free Sample Report

Further, modified polypropylene stands out as an exceptionally robust thermoplastic polymer renowned for its ability to endure harsh weather conditions. Within the building and construction sector, it plays pivotal roles in various critical applications such as sidings, moisture barrier membranes, insulating building wraps, carpet textiles, and the components for piping systems. The utilization of modified polypropylene offers significant advantages in energy efficiency, resilience against adverse weather, and the promotion of eco-friendly roofing solutions. With the escalating pace of urbanization and industrial expansion, particularly in emerging markets, the construction industry is poised for substantial growth, thereby amplifying the demand for modified polypropylene in the foreseeable future.

Modified polypropylene finds extensive application in the packaging industry, where its versatility is highly valued. The increased demand for modified polypropylene stems from the burgeoning packaging sector, a trend primarily fueled by heightened consumerism observed in emerging markets. Regulatory agencies have instituted guidelines governing food packaging, further amplifying the demand for modified polypropylene owing to its chemical resistance properties.

Growth Factors

Increasing Demand from End-Use Industries

Growing demand for modified polypropylene from various end-use industries such as automotive, packaging, construction, and consumer goods is a significant driver of market growth. Modified polypropylene offers enhanced properties such as improved impact resistance, chemical resistance, heat resistance, and stiffness, making it suitable for a wide range of applications across these industries.

Moreover, modified polypropylene serves a vital role in automotive applications, including bumpers, exterior trim, doors, interiors, and various other components. Its appeal lies in a blend of properties, including an excellent balance between impact and stiffness, remarkable flowability, high resistance to impacts and UV rays, and an attractive surface finish. Traditionally, automotive components were crafted from steel or alloys, due to heavier vehicle parts, consequent performance issues, and heightened carbon emissions. As a solution, modified polypropylene is embraced in automobile production to create lightweight vehicles and mitigate carbon emissions.

Favorable Regulatory Norms

The demand for modified polypropylene in automotive applications is anticipated to rise due to increased regulatory measures by the U.S. Environmental Protection Agency (EPA) & the National Highway Traffic Safety Administration (NHTSA), focusing on greenhouse gas emissions and fuel efficiency standards for vehicles. Furthermore, the growing presence of electric vehicles is expected to create lucrative opportunities. Factors such as cost savings on fuel and reduced emissions are likely to fuel the demand for electric vehicles, subsequently driving the consumption of modified polypropylene in automotive applications and contributing to market growth.

Restraining Factors

Food Safety in Packaging Solutions

Food safety remains a paramount concern worldwide, prompting countries to enforce rigorous regulations. These regulations have spurred the adoption of modified polypropylene in packaging solutions. Modified polypropylene, devoid of bisphenol A, mitigates the risk of chemical leaching into packaged foods. Moreover, escalating international trade and the imperative for secure product transportation have elevated the need for industrial packaging, consequently driving up the demand for modified polypropylene in the global packaging sector.

Further, the potential limitations in recyclability and environmental sustainability associated with certain modifications and additives used in its production. This constraint can impact the modified polypropylene market and is characterized by raising concerns among environmentally conscious consumers and regulatory bodies, potentially limiting the adoption of Modified Polypropylene in applications where sustainability is a priority.

Report Segmentation

The market is primarily segmented based on type, application, and region.

|

By Type |

By Application |

By Region |

|

|

|

To Understand the Scope of this Report: Speak to Analyst

By Application Insights

Automotive Segment Accounted for the Largest Market Share in 2023

In 2023, the Automotive segment accounted for the largest market share. Within the automotive industry, there is a push for energy-efficient vehicles as global oil and gas reserves decline. Additionally, regulations concerning vehicle weight and emissions standards are expected to drive the need for modified polypropylene in automotive applications. The properties such as high impact resistance, abrasion resistance, and excellent UV resistance further contribute to the demand for modified polypropylene in automotive components.

The demand for modified polypropylene in packaging applications is anticipated to rise due to its attributes, such as softness, high clarity, chemical resistance, and ease of processing. Factors like heightened health consciousness, evolving lifestyles, and the convenience of packaged foods have propelled the market for packaged food items. Moreover, the onset of the COVID-19 pandemic has underscored the significance of modified polypropylene market insights into packaged foods and medical devices. Given its high resistance to bacteria and chemicals, modified polypropylene is well-suited for use in medical products.

Further, the modified polypropylene market report scope finds application in the building and construction sector owing to its resilience against various weather conditions. It is utilized in the production of plumbing pipes for building structures and moisture barrier membranes for roofing systems. The increasing urbanization in emerging markets, alongside infrastructure development endeavors, is projected to drive the expansion of the construction industry, consequently boosting the requirement for modified polypropylene.

Packaging solutions, another modified polypropylene market segmentation, will grow rapidly. The utilization of modified polypropylene in packaging applications is extensive. Its demand is on the rise, largely fueled by the expanding packaging sector, particularly propelled by heightened consumerism in emerging markets. Regulatory agencies have introduced stringent guidelines concerning food packaging, further elevating the demand for modified polypropylene due to its chemical resistance properties.

Regional Insights

Apac Region Accounted for the Largest Market Share in 2023

In 2023, the APAC region accounted for the largest market share. This dominance stems from the escalating demand for modified polypropylene in vital industries across developing nations like China and India. These industries encompass automotive, electrical and electronics, building and construction, medical, and packaging. The region stands out as one of the primary manufacturing hubs for vehicles and electronic components. The surge in demand for durable electronics and lightweight, high-performance vehicles has propelled the utilization of modified polypropylene within the automotive and electronics sectors.

The establishment of manufacturing facilities by major electrical OEMs in China is expected to drive up the demand for modified polypropylene. Other countries, like Japan and South Korea, have witnessed significant modified polypropylene market growth in the automotive industry. Due to its impact resistance, modified polypropylene finds extensive application in the production of rear and front bumpers, as well as other interior components, for automobiles.

North America Region is Expected to Witness the Fastest Cagr During the Forecast Period

North America region is expected to witness the fastest CAGR during the forecast period. Renowned for its established suppliers and robust domestic demand, especially in automotive sectors, the region reflects a burgeoning market landscape. The region's expanding population and avid interest in automobiles have catalyzed significant growth and advancements within the automotive industry in recent times. Within this competitive landscape, numerous manufacturers vie for market share, each offering distinct product portfolios catering to diverse consumer needs.

Key Market Players & Competitive Insights

The modified polypropylene market report coverage highlights the presence of major players in the market alongside numerous medium and small regional competitors. Established leaders such as Borealis are spearheading innovation in modified polypropylene solutions designed for various applications, giving them a competitive edge over their counterparts.

Some of the major players operating in the global market include:

- Arkema

- Covestro AG

- Kingfa Sci. & Tech Co., Ltd.

- LG Chem

- LyondellBasell Industries Holdings B.V.

- PetroChina Company Limited

- PolyPacific

- SABIC

- Fuzhou Topda New Material Co., Ltd.

- UNINKO

- Xiamen Keyuan Plastic Co.,Ltd

- COACE Chemical Company Ltd.

Recent Developments in the Industry

- In November 2022, LyondellBasell announced an increase in its propylene production capacity in Houston, TX. The potential expansion entails constructing a new propylene facility and leveraging existing technology to convert ethylene into propylene. This additional propylene would serve as a feedstock to produce polypropylene & propylene oxide.

Report Coverage

The modified polypropylene market report emphasizes on key regions across the globe to provide better understanding of the product to the users. Also, the report provides market insights into recent developments, trends and analyzes the technologies that are gaining traction around the globe. Furthermore, the report covers in-depth qualitative analysis pertaining to various paradigm shifts associated with the transformation of these solutions.

The report provides detailed analysis of the market while focusing on various key aspects such as competitive analysis, type, application, and their futuristic growth opportunities.

Modified Polypropylene Market Report Scope

|

Report Attributes |

Details |

|

Market size value in 2024 |

USD 43.24 billion |

|

Revenue forecast in 2032 |

USD 69.00 billion |

|

CAGR |

6.0% from 2024 – 2032 |

|

Base year |

2023 |

|

Historical data |

2019 – 2022 |

|

Forecast period |

2024 – 2032 |

|

Quantitative units |

Revenue in USD billion and CAGR from 2024 to 2032 |

|

Segments covered |

|

|

Regional scope |

|

|

Competitive Landscape |

|

|

Report Format |

|

|

Customization |

Report customization as per your requirements with respect to countries, region, and segmentation. |

FAQ's

The Modified Polypropylene Market report covering key segments are type, application, and region.

Modified Polypropylene Market Size Worth $69.00 Billion By 2032

Modified polypropylene market exhibiting the CAGR of 6.0% during the forecast period.

North America is leading the global market

key driving factors in Modified Polypropylene Market are Increasing Demand from End-Use Industries