Precast Concrete Market Size, Share, Trends, Industry Analysis Report

: By Element (Girders, Columns and Beams, Walls and Barriers, Floors and Roofs, Utility Vaults, Pipes, Paving Slabs, and others), Construction Type, Product, Application, End Use, and Region (North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa) – Market Forecast, 2025–2034

- Published Date:Nov-2024

- Pages: 126

- Format: PDF

- Report ID: PM1582

- Base Year: 2024

- Historical Data: 2020-2023

Precast Concrete Market Overview

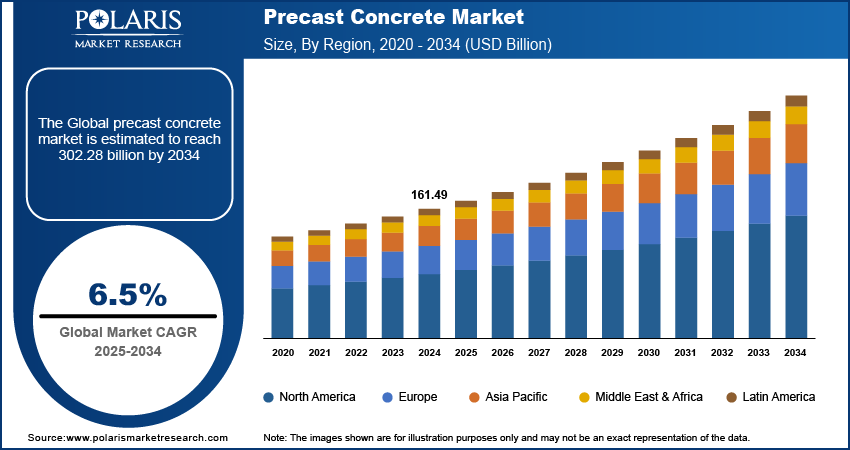

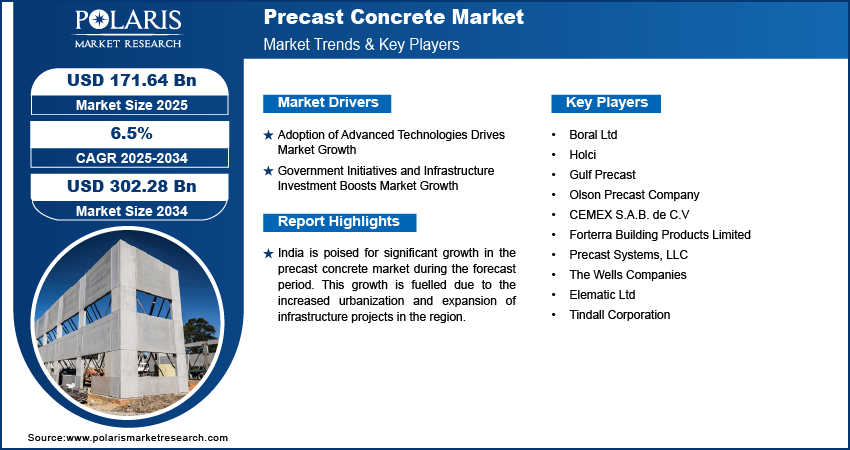

The precast concrete market size was valued at USD 161.49 billion in 2024. The market is projected to grow from USD 171.64 billion in 2025 to USD 302.28 billion by 2034, exhibiting a CAGR of 6.5% from 2025 to 2034.

Precast concrete is a construction material produced by pouring concrete into a preformed mold. The concrete is then allowed to cure in a controlled environment. After the curing process, the mold is extracted and can be utilized again. The resulting precast concrete product is then transported to the construction site for use in the project. Precast concrete is highly regarded for its exceptional quality, flexibility, eco-friendliness, robustness, endurance, and reduced long-term expenses. It is extensively employed in the construction of low- and mid-rise structures, delivering top-notch fire resistance and sound management for individual units.

The cost-effectiveness and efficiency of precast concrete are driving market growth. Traditional construction methods are more time-consuming compared to precast concrete methods. Factory-based production allows for precise quality control and streamlines the construction process. Also, off-site production reduces weather-related delays, lowers on-site labour costs, minimizes construction waste, and improves overall project efficiency. Precast concrete panels and elements can be manufactured in advance and quickly assembled on-site, significantly shortening construction timelines. For instance, in July 2022, Larsen & Toubro announced the completion of a 12-storey residential tower with 96 flats in just 96 days using the precast large concrete panel system, demonstrating the potential for ultra-rapid construction of public housing. The residential tower is part of CIDCO's (City and Industrial Development Corporation) initiative to construct approximately 23,432 EWS and LIG houses under Package IV of the PMAY in Navi Mumbai.

To Understand More About this Research: Request a Free Sample Report

The rapid urbanization and infrastructure development are further driving the market growth. With the expansion of urban areas and increasing population, there is a rise in demand for the development of new residential complexes, commercial facilities, and transportation infrastructure. Precast concrete offers quicker construction with fewer delays, which is crucial in fast-paced urban cities. Its factory-controlled production process ensures consistent quality and reduces construction time, which provides ready materials for the urgent need of infrastructure.

Precast Concrete Market Trends and Drivers Analysis

Adoption of Advanced Technologies

Technological advancements are enhancing production processes, improving quality, and expanding the material's applications, thereby driving market growth. Advanced mixing techniques, automated production lines, and 3D modeling have revolutionized the industry. Technologies such as automated machinery and industrial robotics have streamlined manufacturing processes, increasing efficiency and reducing costs. These innovations enable the production of complex, customized components with greater precision and speed, making precast concrete suitable for a wider range of architectural and structural applications. For instance, in March 2024, Magicrete, a manufacturer of autoclaved aerated concrete (AAC) blocks, construction chemicals, and precast construction solutions, recently announced the successful implementation of a large-scale housing project in Ranchi, India utilizing the advanced 3D Modular Precast Construction System.

Government Initiatives and Infrastructure Investment

Government initiatives, policies, and programs promoting efficient, sustainable, and cost-effective construction methods drive market growth. Many countries have adopted green building standards and sustainable construction guidelines, incentivizing the use of precast concrete due to its energy efficiency and reduced waste generation. For instance, in 2021, the Building Construction Authority (BCA) of Singapore launched the USD 63 million Green Mark Incentive Scheme for Existing Buildings 2.0 (GMIS-EB 2.0), which provides financial incentives for energy efficiency retrofits. This initiative aims to minimize the carbon footprint of buildings through strategies like prioritizing maintainability in design, minimizing embodied carbon throughout the building's life cycle, and fostering healthier indoor environments for occupants. Therefore, government initiatives and investments in infrastructure projects are propelling the market forward.

Precast Concrete Market Segment Analysis

Precast Concrete Market Assessment by Elements Insights

The precast concrete market segmentation, based on elements, includes girders, columns and beams, walls and barriers, floors and roofs, utility vaults, pipes, paving slabs, and others. The columns and beams segment held the largest revenue share of the market. Urbanization and the growing need for sustainable construction techniques in both the commercial and residential domains have heightened the demand for precast columns. These structural components are fabricated off-site under controlled conditions and subsequently delivered to construction sites for installation. Primarily composed of reinforced concrete, precast columns serve to bear the load of the superstructure, including floors, beams, and roofs. For instance, in October 2020, South Dakota State University announced a new patented technology for precast columns and beams. In the patented design, the precast beam is inserted into the column and connected to the column reinforcement using buckling-restrained reinforcement. This connection involves exposed reinforcing bars that are coupled to the beam and column bars. The exposed bars can facilitate easy replacement in case of damage. Thus, innovations in construction techniques are driving growth in the columns and beams segment.

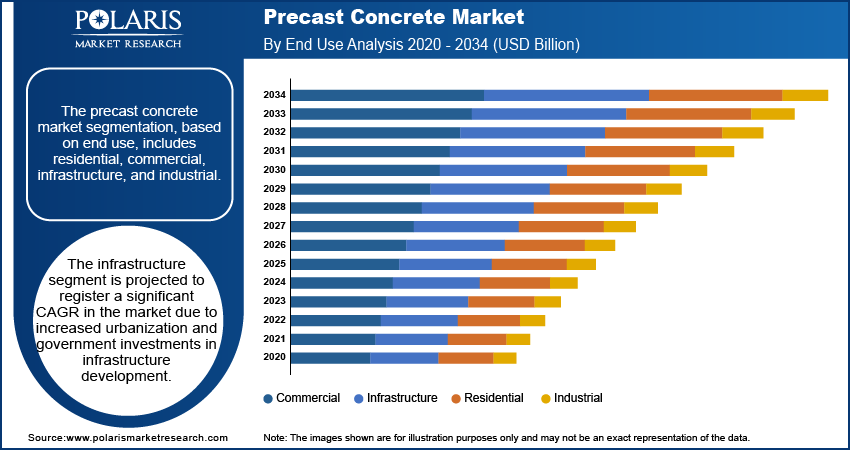

Precast Concrete Market Evaluation by End Use Insights

The precast concrete market segmentation, based on end-use, includes residential, commercial, infrastructure, and industrial. The infrastructure segment is projected to register a significant CAGR in the market due to increased urbanization and government investments in infrastructure development. As the population grows and urban areas expand, there is a need for improved infrastructure, including roads, bridges, and public transit systems. Precast concrete is highly suitable for these applications due to its ability to accelerate construction processes and its proven durability. Besides, governments worldwide are making significant investments in infrastructure to stimulate economic growth and enhance public amenities. For instance, in January 2021, BE Billimoria & Company announced building affordable housing for retired police officers as part of the Maharashtra Police Housing Project. BE Billimoria is utilizing precast concrete technology and machines from Elematic, along with precast construction services from principal contractor IQB, for the construction of the project. Therefore, the infrastructure segment is driving precast concrete market growth.

Precast Concrete Market Breakdown by Regional Insights

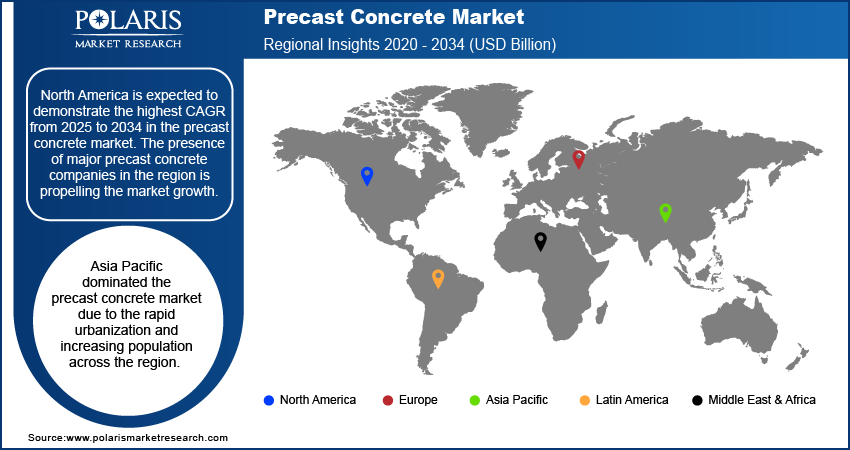

By region, the study provides precast concrete market insights into North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. Asia Pacific accounted for the largest revenue share due to rapid urbanization in the region. Governments are making investments in infrastructure to support economic growth and enhance public amenities. This support from the government is further propelling the precast concrete market.

The precast concrete market in India is expected to have significant growth due to rapid urbanization and the expansion of infrastructure projects, including roads, bridges, and residential complexes in the region. For instance, in June 2022, the Ministry of Road Transport and Highways (MoRTH) of India made it mandatory to use precast concrete in national highway projects within a 100 km radius of the precast factory. This policy is intended to harness the benefits of prefabrication in construction. By ensuring that precast concrete components are used close to production sites, the ministry aims to enhance construction efficiency and project turnaround times while optimizing logistical operations. Therefore, infrastructure expansion and urbanization are driving the market growth in the region.

North America is projected to register a substantial CAGR from 2025 to 2034 due to the presence of major precast concrete companies that are actively expanding their operations and capabilities in the region. For instance, in July 2024, Wells announced the acquisition of GATE Precast, a subsidiary of GATE Petroleum Company. With this acquisition, Wells now has a presence in over 20 locations across the United States, with 14 manufacturing facilities and a total of 2200 team members. The company's reach extends to over 30 states with this acquisition. The demand for efficient and high-quality construction materials continues to rise, and mergers and acquisitions by industry players are propelling the market the growth.

Precast Concrete Market – Key Players & Competitive Insights

The precast concrete market is a dynamic and rapidly evolving environment with several players striving to innovate and differentiate from each other. Major global companies are dominating the market by leveraging extensive research and development capabilities, advanced manufacturing technologies, and broad distribution networks to maintain a competitive edge. The players are engaged in strategic activities such as mergers and acquisitions, partnerships, and collaborations to enhance their product portfolios and expand their market presence.

Startups are also contributing to the market by introducing novel technologies in precast concrete production. This competitive scenario is further intensified by ongoing advancements in technology and increased production of precast materials are growing demand for the precast concrete market. Major players in the precast concrete market include Boral Ltd.; Holcim; Gulf Precast; Olson Precast Company; CEMEX S.A.B. de C.V; Forterra Building Products Limited; Precast Systems, LLC.; The Wells Companies; Elematic Ltd; and Tindall Corporation.

Holcim is a sustainable building solutions company. Holcim employs 63,448 professionals dedicated to decarbonizing construction while enhancing living standards. The company offers a diverse range of low-carbon and circular solutions, such as ECOPact, ECOPlanet, and the circular technology platform ECOCycle®. Holcim's innovative systems, including Elevate roofing and PRB insulation, enhance building sustainability, energy efficiency, and green retrofitting. With sustainability embedded in its core strategy and targets validated by the Science Based Targets initiative (SBTi), Holcim is on track to achieve net-zero emissions and support sustainable infrastructure and affordable housing solutions globally. In June 2024, Holcim announced the acquisition of the Cand-Landi Group in Switzerland as part of its strategic efforts to accelerate decarbonization and promote circular construction practices.

Wells is a precast concrete company specializing in building systems and precast solutions. They offer precast systems that expedite construction through prefabricated components, resulting in improved efficiency and quality. Wells provides specialized consultation on structural enclosures and architectural and structural precast elements. With 12 manufacturing facilities throughout the United States and a workforce of approximately 2,200 employees, Wells has established a robust operational framework. The company undertakes a wide range of construction projects, spanning from residential to large-scale infrastructure developments. In December 2020, Wells Concrete acquired Spancrete. Following the acquisition, Wells will now have a significant presence, spanning Canada, New Mexico, Colorado, and Indiana.

List of Key Companies in the Precast Concrete Market

- Boral Ltd

- Holci

- Gulf Precast

- Olson Precast Company

- CEMEX S.A.B. de C.V

- Forterra Building Products Limited

- Precast Systems, LLC

- The Wells Companies

- Elematic Ltd

- Tindall Corporation

Precast Concrete Market Developments

In April 2024: Holcim announced the acquisition of Tensolite, a manufacturer of precast and pre-stressed concrete construction systems. According to Holcim, Tensolite's wide-ranging presence across Argentina, Paraguay, and Uruguay, including its established plants and distribution network, is set to enhance Holcim's Solutions & Products portfolio.

In June 2024: Brakes India and ADVICS announced a strategic collaboration to co-develop advanced braking systems tailored for the Indian light vehicle market. The partnership builds upon their extensive history of working together and is focused on elevating the braking technology landscape in India.

In September 2022: Tindall Corporation launched a new specialized production line at its Mississippi manufacturing plant for the patented T-SLAB® precast concrete floor slab system. According to Tindall, the T-SLAB, also known as the Tindall Superior Lightweight All-Purpose Beam, outperforms both cast-in-place concrete and hollow core systems with its advanced construction capabilities and superior performance, all within a single, fully precast concrete solution.

Precast Concrete Market Segmentation

By Elements Outlook (Revenue – USD Billion, 2020–2034)

- Girders

- Columns and Beams

- Walls and Barriers

- Floors and Roofs

- Utility Vaults

- Pipes

- Paving Slabs

- Others

By Construction Type Outlook (Revenue – USD Billion, 2020–2034)

- Elemental Construction

- Permanent Modular Buildings

- Relocate Construction

By Product Outlook (Revenue – USD Billion, 2020–2034)

- Wet Concrete

- Dry/Semi-dry Concrete

By Application Outlook (Revenue – USD Billion, 2020–2034)

- Structural Building Components

- Architectural Building Components

- Transportation

- Waste and Water Handling

- Others

By End Use Outlook (Revenue – USD Billion, 2020–2034)

- Residential

- Commercial

- Infrastructure

- Tunnels

- Bridges

- Wind Towers

- Industrial

By Regional Outlook (Revenue – USD Billion, 2020–2034)

- North America

- US

- Canada

- Europe

- Germany

- France

- UK

- Italy

- Spain

- Netherlands

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Malaysia

- South Korea

- Indonesia

- Australia

- Rest of Asia Pacific

- Middle East & Africa

- Saudi Arabia

- UAE

- Israel

- South Africa

- Rest of the Middle East & Africa

- Latin America

- Mexico

- Brazil

- Argentina

- Rest of Latin America

Precast Concrete Report Scope

|

Report Attributes |

Details |

|

Market Size Value in 2024 |

USD 161.49 billion |

|

Market Size Value in 2025 |

USD 171.64 billion |

|

Revenue Forecast in 2034 |

USD 302.28 billion |

|

CAGR |

6.5% from 2025 to 2034 |

|

Base Year |

2024 |

|

Historical Data |

2020–2023 |

|

Forecast Period |

2025–2034 |

|

Quantitative Units |

Revenue in USD Billion and CAGR from 2025 to 2034 |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

|

|

Regional Scope |

|

|

Competitive Landscape |

|

|

Report Format |

|

|

Customization |

Report customization as per your requirements with respect to countries, regions, and segmentation. |

FAQ's

The precast concrete market size was valued at USD 161.49 billion in 2024 and is projected to grow to USD 302.28 billion by 2034.

The market is projected to grow at a CAGR of 6.5% from 2025 to 2034.

Asia Pacific had the largest share of the market.

The key players in the market are Boral Ltd.; Holcim; Gulf Precast; Olson Precast Company; CEMEX S.A.B. de C.V; Forterra Building Products Limited; Precast Systems, LLC.; The Wells Companies; Elematic Ltd; and Tindall Corporation.

The columns and beams segment accounted for a significant revenue share due to the growing need for sustainable construction techniques in both the commercial and residential domains.

The infrastructure segment is anticipated to witness significant growth due to the increasing population and rapid urbanization in the region.