Freeze Drying Equipment Market Size, Share, Trends, Industry Analysis Report

By Product (Bench Top Freeze Dryers, Floor Freeze Dryers), By Type, By Application, By Region – Market Forecast, 2025–2034

- Published Date:Oct-2025

- Pages: 117

- Format: PDF

- Report ID: PM1634

- Base Year: 2024

- Historical Data: 2020-2023

Market Overview

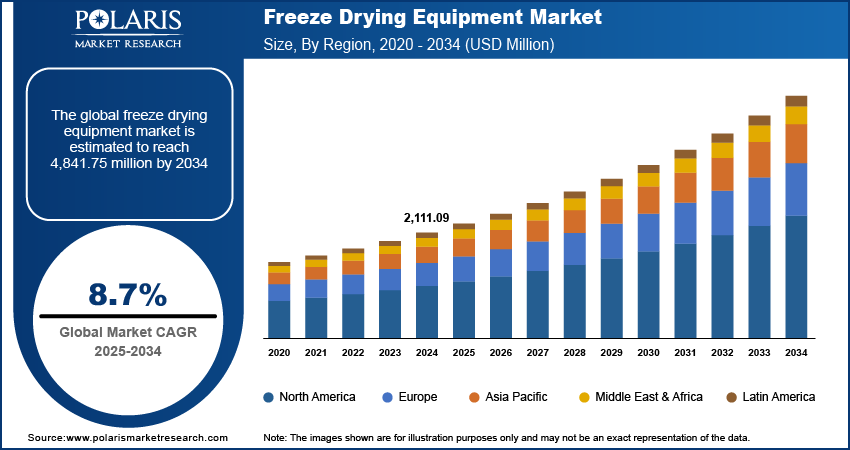

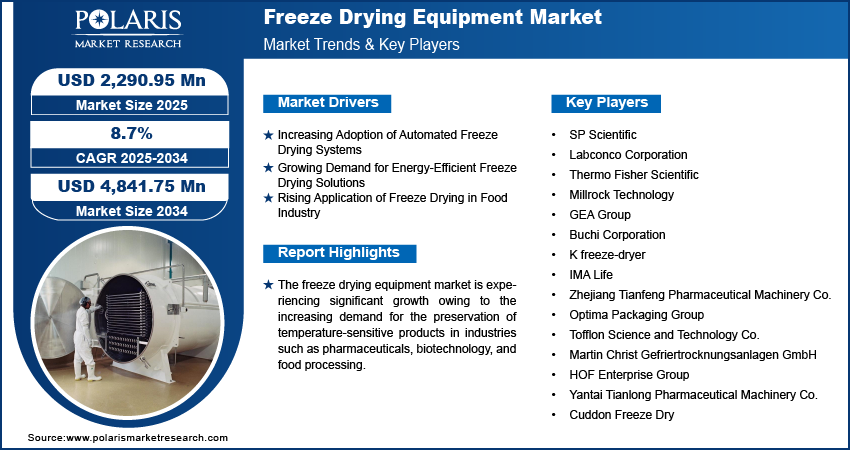

The global freeze drying equipment market size was valued at USD 2,111.09 million in 2024 and is projected to register a CAGR of 8.7% from 2025 to 2034. The demand for high-quality and preserved biological samples for research and diagnostics propels market growth. Also, rising demand for convenient and durable products contributes to the increasing demand for freeze drying equipment.

Key Insights

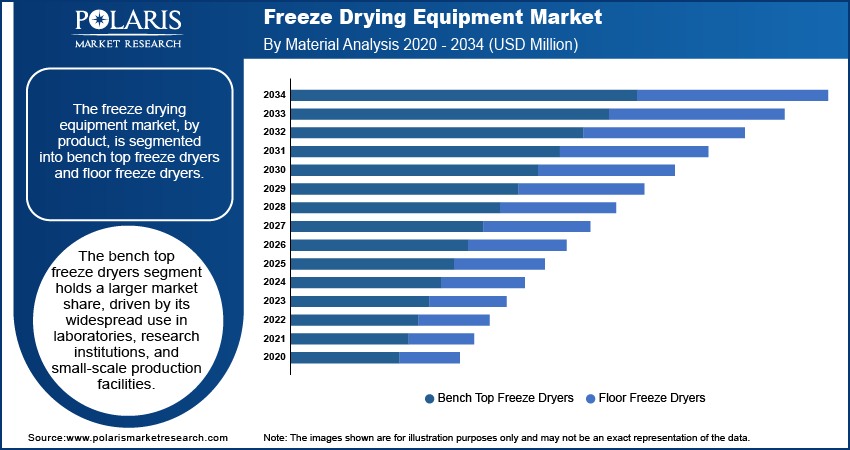

- The bench top freeze dryers segment held the largest share in 2024. It is driven by its widespread use in laboratories, research institutions, and small-scale production facilities.

- The industrial freeze dryers segment held the largest revenue share in 2024. The dominance is attributed to its essential role in large-scale production across sectors, such as pharmaceuticals, food processing, and biotechnology.

- In 2024, the biotechnology and pharmaceutical segment held the largest share. The critical role of freeze drying in preserving biological products, pharmaceuticals, and vaccines contributes to this dominance.

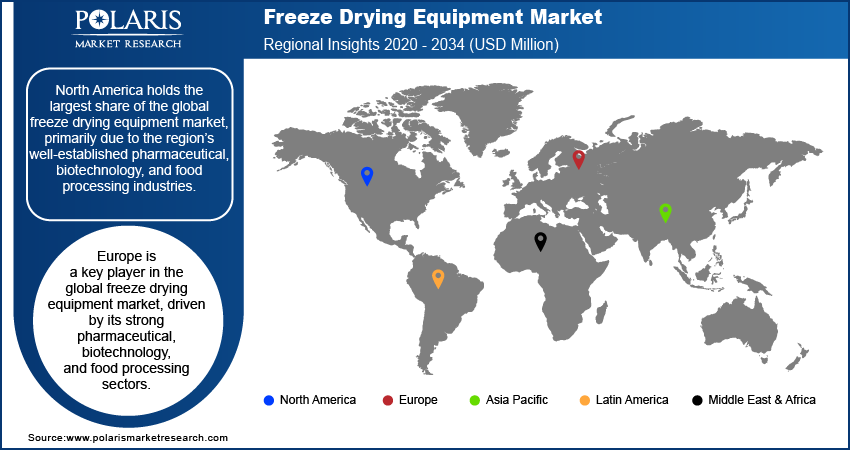

- North America accounted for the largest global revenue share in 2024. The region’s well-established pharmaceutical, biotechnology, and food processing industries boost its leading position.

- The Asia Pacific freeze drying equipment industry is experiencing rapid growth. The growth is fueled by the expanding pharmaceutical and food processing industries, particularly in countries such as China, India, and Japan.

Industry Dynamics

- Increasing demand for energy-efficient freeze drying solutions fuels the market development.

- The use of freeze drying is expanding in the food industry, which propels the freeze drying equipment industry expansion.

- The rising adoption of automated freeze drying systems is expected to emerge as a major trend in the coming years.

- Requirement of high initial investments hinders the growth of the market.

Market Statistics

- 2024 Market Size: USD 2,111.09 million

- 2034 Projected Market Size: USD 4,841.75 million

- CAGR (2025–2034): 8.7%

- North America: Largest market in 2024

AI Impact on Freeze Drying Equipment Market

- Artificial intelligence (AI) algorithms predict drying times based on material type and quantity. It enables precise control over the freeze-drying process. This process improves throughput and lowers energy consumption.

- AI-enabled systems are used to monitor equipment health in real time. They identify potential failures before they happen. This reduces downtime and maintenance costs, which is highly valuable in pharmaceutical and biotech applications.

- Smart freeze dryers equipped with AI and IoT sensors facilitate continuous monitoring, ensuring compliance with safety standards and consistent product quality.

- In Industry 4.0, AI enables automation, robotics, and blockchain integration for traceability and export compliance.

To Understand More About this Research: Request a Free Sample Report

Freeze drying equipment is designed to preserve materials by removing moisture through sublimation. This method, also known as lyophilization, is widely used across various industries, particularly in pharmaceuticals, biotechnology, food processing, and nutraceuticals. Key drivers of the freeze drying equipment market growth are the rising demand for pharmaceutical products with extended shelf life, advancements in biotechnological applications, and an increasing preference for natural food products. Additionally, the integration of automation in freeze-drying processes, the development of energy-efficient equipment, and increased adoption in the cosmetics industry are shaping the market growth. The demand for high-quality and preserved biological samples for research and diagnostics also propels market growth, highlighting the critical role of freeze drying in maintaining product integrity across sectors.

Market Drivers and Trends

Increasing Adoption of Automated Freeze Drying Systems

The freeze drying equipment market is seeing a significant shift toward automation as industries aim to improve efficiency, precision, and scalability in lyophilization processes. Automated freeze drying systems streamline operations by reducing manual intervention. They minimize contamination risks and ensure consistent product quality. According to a study by Technavio, automation in freeze drying can lower operational costs by up to 20% due to reduced labor requirements and enhanced precision. Automated systems are particularly beneficial in the pharmaceutical and biotechnology sectors, where precise control over temperature and pressure is critical. As manufacturers prioritize efficiency in high-demand applications such as vaccine production, biologics, and biopharmaceuticals, the rising adoption of automated freeze drying systems will become a major freeze drying equipment market trend in the coming years.

Growing Demand for Energy-Efficient Freeze Drying Solutions

Energy efficiency has become a key focus for manufacturers and end users in the freeze drying equipment market, driven by the high energy costs associated with traditional freeze drying processes. As a result, companies are increasingly investing in equipment that incorporates energy-saving technologies to minimize costs and environmental impact. Research by the U.S. Department of Energy indicates that energy-efficient freeze-drying systems can reduce energy consumption by 15–30%, which is crucial for large-scale operations in food processing and pharmaceutical sectors. These advancements contribute to sustainability and enhance the overall affordability and feasibility of freeze drying for a broader range of applications. Thus, increasing demand for energy-efficient freeze drying solutions fuel the freeze drying equipment market expansion.

Rising Application of Freeze Drying in Food Industry

The use of freeze drying is expanding in the food industry, propelled by rising consumer demand for longer shelf life and high-quality, preservative-free products. Freeze drying retains nutritional value and flavor better than other preservation methods, making it popular for producing dried fruits, instant coffee, and ready meals. A report by the National Institute of Food and Agriculture highlights that freeze drying can preserve up to 97% of nutritional content, making it one of the most effective drying techniques available. This trend would be fueled by the growing market for convenience foods and health-conscious consumer preferences, which are prompting more food producers to adopt freeze drying technology in their production lines.

Segment Insights

Market Outlook – Product-Based Insights

The freeze drying equipment market, by product, is segmented into bench top freeze dryers and floor freeze dryers. The bench top freeze dryers segment holds a larger market share, driven by its widespread use in laboratories, research institutions, and small-scale production facilities. Bench top freeze dryers are compact, user-friendly, and capable of handling smaller batches, making them ideal for applications requiring controlled lyophilization in limited space. Their ease of integration and suitability for various testing and formulation procedures within academic, pharmaceutical, and biotechnology labs add to their appeal. Additionally, bench top models often feature precise temperature and pressure controls, enhancing their role in sensitive applications such as diagnostic research and sample preservation.

The floor freeze dryers segment is experiencing the highest growth rate, primarily due to the increased demand for floor freeze dryers in high-end research and pharmaceutical production settings. These units are engineered for larger capacity and advanced functionality, making them suitable for clinical trials, bulk lyophilization, and industrial-scale product testing. Growing emphasis on vaccine and biologics development has further accelerated adoption, as floor freeze dryers support the preservation of complex biomolecules with enhanced reliability. This segment’s expansion is fueled by advancements in pharmaceutical and biotechnological research, where the need for scalable, precise freeze drying solutions continues to rise.

Market Outlook – Type-Based Insights

The freeze drying equipment market, by type, is segmented into industrial freeze dryers, laboratory freeze dryers, and general purpose freeze dryers. The industrial freeze dryers segment holds the largest market share, attributed to its essential role in large-scale production across sectors such as pharmaceuticals, food processing, and biotechnology. Industrial freeze dryers are designed for high-capacity applications, making them integral in producing bulk materials with consistent quality, especially where high-throughput lyophilization is needed. Their capacity to handle larger product volumes and ensure precise control over drying conditions makes them ideal for continuous operations in manufacturing facilities, where efficiency and scalability are key. The industrial segment’s prominence is further supported by advancements in technology that enhance energy efficiency and process reliability, essential for industries with stringent regulatory requirements.

The laboratory freeze dryers segment is registering the highest growth rate, fueled by increasing applications in pharmaceutical research, biotechnology, and academic settings. The demand for laboratory freeze dryers is primarily driven by their precision and versatility, which are critical in preserving biological samples, preparing diagnostic materials, and conducting experimental studies. Their adaptability for smaller batch sizes and specialized research needs has made them increasingly popular in institutions focusing on vaccine development, biologics, and personalized medicine. As research activities expand in these fields, the need for precise and flexible freeze drying solutions is growing, contributing to the strong growth rate of laboratory freeze dryers.

Market Outlook – Application-Based Insights

The freeze drying equipment market, by application, is segmented into biotechnology & pharmaceutical, food processing, surgical procedures, and others. The biotechnology and pharmaceutical segment holds the largest market share, driven by the critical role of freeze drying in preserving biological products, pharmaceuticals, and vaccines. The demand within this sector is fueled by the increasing production of temperature-sensitive materials that require reliable preservation techniques to maintain efficacy. Freeze drying, or lyophilization, is essential in stabilizing active pharmaceutical ingredients, proteins, and complex biological samples. As a result, pharmaceutical and biotechnology companies invest heavily in advanced freeze drying equipment to meet regulatory standards and ensure product stability throughout transportation and storage, particularly in biologics, vaccines, and injectable formulations.

The food processing segment is experiencing the highest growth due to rising consumer demand for natural, minimally processed food products with extended shelf life. Freeze drying in food processing preserves nutritional content, taste, and texture, making it a preferred method for products such as fruits, vegetables, coffee, and ready-to-eat meals. The trend toward clean-label products, coupled with the increased popularity of convenience foods, is driving the adoption of freeze drying technology in this industry. Innovations that enhance energy efficiency and scalability in food processing freeze dryers also contribute to this segment's rapid growth, as manufacturers seek to optimize production while retaining product quality and appeal.

Regional Insights

By region, the study provides freeze drying equipment market insights into North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. North America holds the largest market share, primarily due to the region’s well-established pharmaceutical, biotechnology, and food processing industries. The strong presence of major pharmaceutical companies and research institutions in the US and Canada drives the demand for advanced freeze drying technologies, particularly in the production of biologics, vaccines, and other temperature-sensitive pharmaceutical products. Additionally, North America benefits from significant investments in healthcare research and development, where precise preservation methods such as freeze drying are critical. The region’s focus on sustainability and energy-efficient solutions also supports the market growth, as manufacturers seek to optimize operations and reduce environmental impact. Furthermore, the robust regulatory framework and the increasing need for high-quality, shelf-stable food products further boost the region’s dominance in the freeze drying equipment market.

Europe is a key player in the freeze drying equipment market, driven by its strong pharmaceutical, biotechnology, and food processing sectors. The region is home to many leading pharmaceutical companies, which require advanced freeze drying technology to produce stable vaccines, biologics, and other sensitive medicines. Additionally, Europe has been investing heavily in sustainable food production and preservation, where freeze drying plays an essential role in extending the shelf life of food products without compromising quality. The increasing demand for natural, clean-label foods and the growing trend toward healthy eating are propelling the adoption of freeze drying equipment in the food industry. Furthermore, Europe’s stringent regulatory environment supports the demand for high-precision freeze drying equipment, especially in pharmaceuticals and research.

The Asia Pacific freeze drying equipment market is experiencing rapid growth, fueled by expanding pharmaceutical and food processing industries, particularly in countries such as China, India, and Japan. In the pharmaceuticals industry, the rising focus on biologics and vaccine production, especially in light of the global pandemic, is driving the demand for freeze drying technologies. The region's burgeoning food processing industry is also a major contributor, as demand for freeze-dried foods such as fruits, vegetables, and ready-to-eat meals continues to grow. The rise in disposable income and changing consumer preferences toward convenience and health-conscious products further accelerate the adoption of freeze drying equipment in the food sector. Additionally, increasing investments in healthcare infrastructure and research activities in biotechnology are expected to boost the freeze drying equipment market growth in the region.

Key Players and Competitive Insights

SP Scientific, Labconco Corporation, Thermo Fisher Scientific, Millrock Technology, and GEA Group are a few key players in the freeze drying equipment market. Other notable companies include Buchi Corporation, K freeze-dryer, IMA Life, Zhejiang Tianfeng Pharmaceutical Machinery Co., Optima Packaging Group, Tofflon Science and Technology Co., Martin Christ Gefriertrocknungsanlagen GmbH, HOF Enterprise Group, Yantai Tianlong Pharmaceutical Machinery Co., Cuddon Freeze Dry, and MechaTech Systems. These companies are involved in designing, manufacturing, and supplying freeze drying equipment across various industries such as pharmaceuticals, biotechnology, food processing, and research. While some companies specialize in high-capacity industrial freeze dryers, others focus on laboratory and small-scale equipment, offering solutions that cater to different segments of the market.

In terms of competitive dynamics, the freeze drying equipment market is characterized by a strong focus on product innovation, efficiency, and customer-specific solutions. Companies are increasingly integrating automation, energy-efficient technologies, and advanced control systems into their equipment to improve operational performance and reduce costs. The competition is also shaped by the need for compliance with stringent regulatory standards, particularly in the pharmaceutical and biotechnology sectors. This has led to greater emphasis on providing high-quality and reliable freeze drying systems that meet industry-specific requirements, such as those for biologics or sensitive food products.

While some companies differentiate themselves through technological advancements, others focus on customer service, offering tailored solutions and support for installation, training, and maintenance. The ongoing demand for sustainable and energy-efficient equipment further drives innovation, with several players focusing on reducing the environmental impact of freeze drying processes. Strategic partnerships, mergers and acquisitions, and collaborations are also common in the market as companies seek to expand their product portfolios, access new markets, and leverage complementary technologies. As competition intensifies, companies that can balance cost-effectiveness with high performance, while meeting diverse customer needs, are likely to continue performing well in the market.

SP Scientific is a company that designs and manufactures equipment for freeze drying, focusing on applications in pharmaceuticals, biotechnology, and food processing. The company offers a range of freeze dryers, lyophilizers, and related equipment, as well as services for installation and maintenance. SP Scientific is recognized for its focus on precision and reliability in its product offerings, which are used in various sectors to preserve sensitive materials through the freeze drying process.

Thermo Fisher Scientific is a global player in scientific instrumentation and laboratory equipment, with a product range that includes freeze dryers used in research, pharmaceuticals, and other industries. The company is known for its innovation and technological advancements in equipment design, providing solutions for small-scale research to large-scale production. Thermo Fisher's products are often used in laboratories for preserving biological samples, formulations, and food products.

List Of Key Companies

- SP Scientific

- Labconco Corporation

- Thermo Fisher Scientific

- Millrock Technology

- GEA Group

- Buchi Corporation

- K freeze-dryer

- IMA Life

- Zhejiang Tianfeng Pharmaceutical Machinery Co.

- Optima Packaging Group

- Tofflon Science and Technology Co.

- Martin Christ Gefriertrocknungsanlagen GmbH

- HOF Enterprise Group

- Yantai Tianlong Pharmaceutical Machinery Co.

- Cuddon Freeze Dry

Freeze Drying Equipment Industry Developments

- In August 2023, SP Scientific introduced a new line of freeze-drying systems aimed at improving the efficiency and scalability of lyophilization processes, responding to the increasing demand for high-quality production systems in biotechnology and pharmaceutical manufacturing.

- In July 2023, Thermo Fisher Scientific launched a new freeze drying system designed to enhance productivity and reduce energy consumption in laboratory environments, catering to increasing needs for efficiency in scientific research and production.

Freeze Drying Equipment Market Segmentation

By Product Outlook

- Bench Top Freeze Dryers

- Floor Freeze Dryers

By Type Outlook

- Industrial Freeze Dryers

- Laboratory Freeze Dryers

- General Purpose Freeze Dryers

By Application Outlook

- Biotechnology & Pharmaceutical

- Food Processing

- Surgical Procedures

- Others

By Regional Outlook

- North America

- US

- Canada

- Europe

- Germany

- France

- UK

- Italy

- Spain

- Netherlands

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Malaysia

- South Korea

- Indonesia

- Australia

- Vietnam

- Rest of Asia Pacific

- Middle East & Africa

- Saudi Arabia

- UAE

- Israel

- South Africa

- Rest of Middle East & Africa

- Latin America

- Mexico

- Brazil

- Argentina

- Rest of Latin America

Freeze Drying Equipment Market Report Scope

|

Report Attributes |

Details |

|

Market Size Value in 2024 |

USD 2,111.09 million |

|

Market Size Value in 2025 |

USD 2,290.95 million |

|

Revenue Forecast by 2034 |

USD 4,841.75 million |

|

CAGR |

8.7% from 2025 to 2034 |

|

Base Year |

2024 |

|

Historical Data |

2020-2023 |

|

Forecast Period |

2025–2034 |

|

Quantitative Units |

Revenue in USD million and CAGR from 2025 to 2034 |

|

Report Coverage |

Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

|

Segments Covered |

|

|

Regional Scope |

|

|

Competitive Landscape |

|

|

Report Format |

|

|

Customization |

Report customization as per your requirements with respect to countries, regions, and segmentation. |

FAQ's

The global freeze drying equipment market value reached USD 2,111.09 million in 2024 and is projected to grow to USD 4,841.75 million by 2034.

The global market is projected to register a CAGR of 8.7% during 2025–2034.

North America held the largest share of the global market in 2024.

A few key players in the freeze drying equipment market are SP Scientific, Labconco Corporation, Thermo Fisher Scientific, Millrock Technology, and GEA Group. Other notable companies include Buchi Corporation, K freeze-dryer, IMA Life, Zhejiang Tianfeng Pharmaceutical Machinery Co., Optima Packaging Group, Tofflon Science and Technology Co., Martin Christ Gefriertrocknungsanlagen GmbH, HOF Enterprise Group, Yantai Tianlong Pharmaceutical Machinery Co., Cuddon Freeze Dry, and MechaTech Systems.

The bench top freeze dryer segment accounted for a larger share of the global market in 2024.

The industrial freeze dryers segment accounted for the largest share of the global market in 2024.

Freeze drying equipment is used to remove moisture from materials by freezing them and then gradually reducing the pressure to allow the ice to sublimate, turning directly into vapor. This process, known as lyophilization, helps preserve the structure, flavor, and nutrients of the material, making it ideal for pharmaceuticals, biotechnology, and food products that require long-term storage without degradation.

A few key trends in the freeze drying equipment market are described below: Automation Integration: Increasing adoption of automated freeze drying systems to improve efficiency, reduce labor costs, and ensure consistent product quality. Energy Efficiency: Growing demand for energy-efficient freeze drying solutions to lower operational costs and reduce environmental impact. Customization for Biopharmaceuticals: Rising demand for freeze dryers tailored to specific pharmaceutical applications, such as biologics, vaccines, and complex proteins. Sustainability Focus: Emphasis on sustainable technologies, with companies developing equipment that minimizes energy consumption and environmental impact.

A new company entering the freeze drying equipment market must focus on developing energy-efficient, cost-effective solutions that cater to the growing demand for sustainability in various industries. Offering customized equipment for niche sectors such as biopharmaceuticals, especially in vaccine and biologics production, could help differentiate the company. Emphasizing automation and advanced control systems to improve process efficiency and reduce human error would also appeal to cost-conscious customers.

Companies producing freeze drying equipment and related products, healthcare providers, and other consulting firms must buy the report.