Low Pressure Die Casting Machines Market Size, Share, & Trends, Analysis Report

By Type (Horizontal and Vertical), By Product, By End Use, and By Region – Market Forecast, 2025–2034

- Published Date:Jun-2025

- Pages: 129

- Format: PDF

- Report ID: PM5754

- Base Year: 2024

- Historical Data: 2020-2023

Market Overview

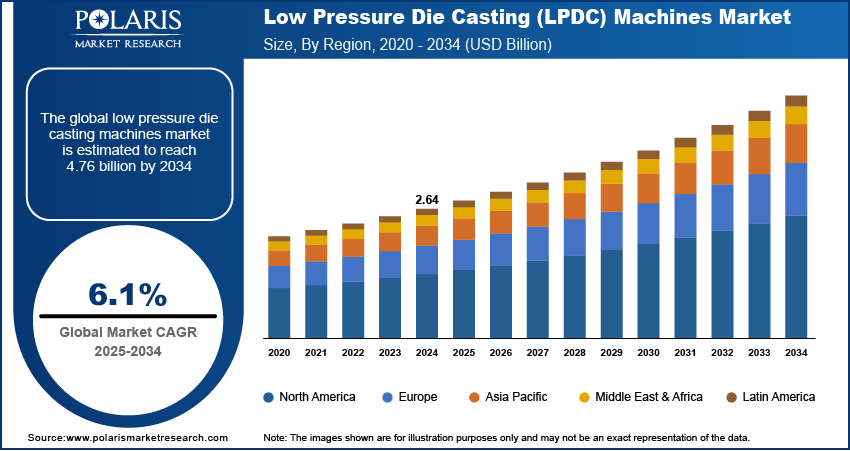

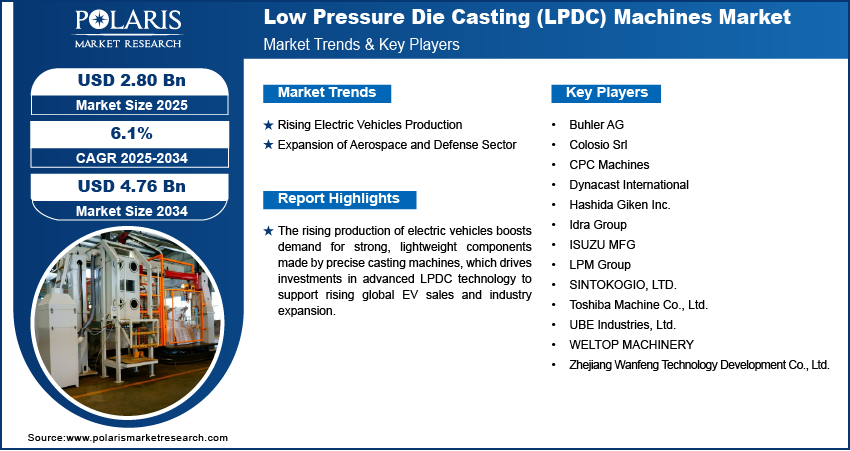

The global low pressure die casting machines market size was valued at USD 2.64 billion in 2024, growing at a CAGR of 6.1% during 2025–2034. The market growth is driven by the rising production of electric cars and the expansion of the aerospace & defense sector.

Low pressure die casting (LPDC) machines are used to produce high-quality metal parts by filling a mold with molten metal using controlled low pressure, typically from a sealed furnace below the mold. This process allows for precise control, reduced porosity, and is ideal for casting complex, lightweight components, especially in aluminum alloys.

Aluminum alloys are becoming more popular across industries as they are light, corrosion-resistant, and easy to cast. According to ThyssenKrupp Materials, the aluminum alloy was the most used alloy for aircraft production in 2024. These machines are especially suitable for working with aluminum, allowing for smooth finishes and high structural integrity. The demand for machines that efficiently cast aluminum has grown as industries move away from heavier materials such as steel. LPDC machines provide better control and fewer defects than other methods, making them the preferred choice, thereby driving industry growth.

.

To Understand More About this Research: Request a Free Sample Report

Technological advancements such as automation, real-time monitoring, and energy-efficient systems are making these machines more attractive. These advancements allow for faster production, better quality control, and reduced waste, which are major priorities for manufacturers. Companies are adopting or upgrading to LPDC systems as casting machines are becoming smarter and more user-friendly. This ongoing innovation attracts a wider range of industries to switch to LPDC technology, driving the demand for these advanced machines.

Industry Dynamics

Rising Electric Vehicles Production

Electric vehicles (EVs) require strong and lightweight components to improve battery performance and overall range. Casting machines are widely used in making aluminum housings, battery cases, and motor components due to their precision and efficiency. Automakers are investing more in advanced manufacturing equipment due to rising global EV sales each year. According to the International Energy Agency, electric car sales worldwide were 17 million in 2024 and rose by 25% from last year. This shift creates new opportunities for machine manufacturers and makes LPDC technology essential in supporting the fast-paced growth of the EV market, thereby driving industry growth.

Expansion of Aerospace and Defense Sector

The aerospace and defense sector requires parts that are lightweight but extremely strong, such as aircraft brackets, frames, and housings. Casting machines produce these parts with high dimensional accuracy and low porosity, making them a reliable option. The need for efficient manufacturing solutions such as LPDC is rising as the sector is growing worldwide. According to the Aerospace Industries Association, in the US alone, the aerospace industry employs 2.211 million people. Additionally, LPDC machines help meet the strict quality and safety standards in the aerospace sector, thereby driving the industry growth.

Segmental Insights

By Product Analysis

The segmentation, based on product, includes automatic, semi-automatic, and manual. In 2024, the automatic segment dominated with the largest share due to their high efficiency, consistent output, and reduced reliance on manual labor. These machines offer faster production rates and improved precision, which are essential for industries requiring large-scale, high-quality metal components. Automation further minimizes errors and improves worker safety, making them the preferred choice across many sectors, including automotive and industrial manufacturing, thereby driving the segment growth.

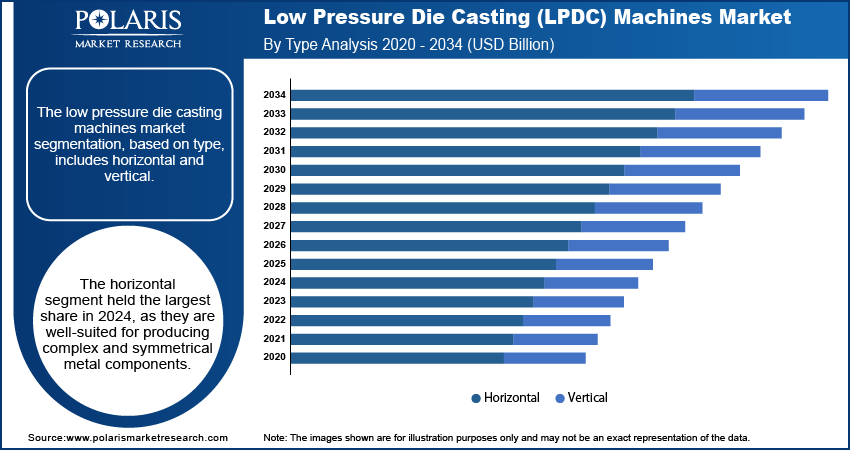

By Type Analysis

The segmentation, based on type, includes horizontal and vertical. The horizontal segment held the largest share in 2024, as they are well-suited for producing complex and symmetrical metal components. These machines offer better control over the filling process, leading to improved surface finish and structural integrity. Their design allows easier maintenance and integration into automated production lines, making them popular in the automotive and heavy machinery industries, thereby driving the growth of the segment.

The vertical segment is expected to experience significant growth during the forecast period, due to its ability to save floor space and efficiently produce tall or asymmetrical parts. These machines are increasingly being adopted in niche applications where horizontal machines may fall short. Advancements in design and control systems have improved their performance, making them more attractive to industries seeking to improve flexibility and reduce production footprint, thereby driving the segment demand during the forecast period.

By End Use Analysis

The segmentation, based on end use, includes automotive, aerospace, electronics, construction, and others. The aerospace segment is expected to record significant growth, driven by the need for lightweight, high-strength components. These machines allow the production of parts with superior dimensional accuracy and minimal porosity, which are critical in aerospace applications. The need for lightweight metal components such as engine housings and structural parts grows as the demand for fuel-efficient aircraft increases, thereby driving the segment growth.

Regional Analysis

Low Pressure Die Casting Machines Market in Asia Pacific

The Asia Pacific low pressure die casting machines market dominated with the largest share in 2024, due to increasing industrialization and demand in the automotive, aerospace, and electronics sectors. Countries such as India, Japan, South Korea, and Australia are investing heavily in modern manufacturing technologies. The region benefits from a strong labor force and supportive government policies encouraging manufacturing advancements. Additionally, rising urbanization and infrastructure development boost demand for lightweight, durable metal components, thereby driving the Asia Pacific low pressure die casting machines industry.

Low Pressure Die Casting Machines Market in China

The China low pressure die casting machines market is expected to witness significant growth driven by its huge automotive and electronics manufacturing industries. The country’s focus on upgrading traditional manufacturing with automated and energy-efficient machines is increasing adoption. Strong government initiatives promoting advanced manufacturing and “Made in China 2025” goals are pushing for higher-quality production processes. Additionally, China’s large domestic demand for automotive, combined with exports to global regions, further drives the demand for low pressure die casting machines. Moreover, the availability of cost-effective raw materials and skilled labor is driving the China low pressure die casting machine industry.

Low Pressure Die Casting Machines Market in North America

The North America low pressure die casting machines market is projected to witness substantial growth driven by a strong industrial base, particularly in automotive, aerospace, and heavy machinery. The US, Canada, and Mexico have been focusing on improving product quality and reducing production costs through advanced die casting technologies. Increasing demand for lightweight material components to improve fuel efficiency and meet environmental regulations is further driving the growth. Additionally, technological innovations, such as automation and IoT integration, are making production processes more efficient, thereby propelling the growth of the industry in the region.

Low Pressure Die Casting Machines Market in US

The US low pressure die casting machines market is expected to experience significant growth during the forecast period, driven by advanced manufacturing infrastructure and high technology adoption. The presence of large automotive and aerospace industries is driving demand, seeking lightweight and high-strength components to meet safety and fuel economy standards. Additionally, investments in smart manufacturing and Industry 4.0 are improving machine performance and reducing costs. Additionally, environmental regulations are encouraging manufacturers to adopt energy-efficient casting machines. Moreover, the US benefits from skilled labor and R&D, which fosters innovation and high-quality output, thereby driving the demand for LPDC machines.

Low Pressure Die Casting Machines Market in Europe

The Europe low pressure die casting machines market is expected to experience substantial growth during the forecast period, due to rising demand from the automotive, aerospace, and industrial machinery sectors. Countries such as Germany, France, and Italy are focusing on producing lightweight and durable metal parts to meet strict environmental and safety standards. The region is further largely investing in advanced manufacturing technologies such as automation and digitalization to improve efficiency. Additionally, government policies supporting sustainable manufacturing and innovation are driving the adoption of LPDC machines. Moreover, Europe’s emphasis on reducing emissions and improving fuel efficiency drives demand for high-quality die casting components.

Germany Low Pressure Die Casting Machines Market in Germany

The LPDC machines market growth in Germany is driven by its robust automotive and machinery industries. Germany focuses on producing high-performance, lightweight metal parts to meet stringent quality and environmental regulations. Investments in Industry 4.0 and smart manufacturing technologies enable German manufacturers to improve efficiency and reduce waste. Additionally, the country’s strong R&D capabilities and skilled workforce support continuous innovation in casting processes. Moreover, Germany’s commitment to sustainability encourages the adoption of energy-efficient machines, thereby driving the growth.

Key Players and Competitive Analysis Report

The low pressure die casting machine industry is highly competitive, with major players offering advanced solutions for automotive, aerospace, and industrial applications. Leading companies such as Buhler AG, Idra Group, and SINTOKOGIO, LTD. are known for their innovation and global reach. Manufacturers such as CPC Machines, LPM Group, and Hashida Giken Inc. focus on specialized LPDC technologies. Meanwhile, firms such as UBE Industries, Dynacast, and ISUZU MFG bring strong manufacturing capabilities. Colosio Srl, WELTOP MACHINERY, and Wanfeng Technology provide cost-effective regional alternatives. This diverse landscape drives technological advancement, efficiency, and customization to meet evolving industry demands.

Key Players

- Buhler AG

- Colosio Srl

- CPC Machines

- Dynacast International

- Hashida Giken Inc.

- Idra Group

- ISUZU MFG

- LPM Group

- SINTOKOGIO, LTD.

- Toshiba Machine Co., Ltd.

- UBE Industries, Ltd.

- WELTOP MACHINERY

- Zhejiang Wanfeng Technology Development Co., Ltd.

Industry Developments

In October 2023, LK Group unveiled the Dreampress 16000T die-casting machine, setting a new benchmark in single-piece casting technology and reinforcing its leadership in advanced manufacturing for the global automotive and die-casting industries.

In October 2022, LK Group launched the world’s first 12,000T intelligent die-casting unit in Shanghai, marking a major technological breakthrough in large-scale integrated casting for new energy vehicles and reinforcing its leadership in the global die-casting industry.

Low Pressure Die Casting Machines Market Segmentation

By Product Outlook (Revenue, USD Billion, 2020–2034)

- Automatic

- Semi-automatic

- Manual

By Type Outlook (Revenue, USD Billion, 2020–2034)

- Horizontal

- Vertical

By End Use Outlook (Revenue, USD Billion, 2020–2034)

- Automotive

- Aerospace

- Electronics

- Construction

- Others

By Regional Outlook (Revenue, USD Billion, 2020–2034)

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- France

- UK

- Italy

- Spain

- Netherlands

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Malaysia

- South Korea

- Indonesia

- Australia

- Vietnam

- Rest of Asia Pacific

- Middle East & Africa

- Saudi Arabia

- UAE

- Israel

- South Africa

- Rest of Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America

Low Pressure Die Casting (LPDC) Machines Market Report Scope

|

Report Attributes |

Details |

|

Market Size Value in 2024 |

USD 2.64 Billion |

|

Market Size Value in 2025 |

USD 2.80 Billion |

|

Revenue Forecast by 2034 |

USD 4.76 Billion |

|

CAGR |

6.1% from 2025 to 2034 |

|

Base Year |

2024 |

|

Historical Data |

2020–2023 |

|

Forecast Period |

2025–2034 |

|

Quantitative Units |

Revenue in USD Billion and CAGR from 2025 to 2034 |

|

Report Coverage |

Revenue Forecast, Competitive Landscape, Growth Factors, and Industry Trends |

|

Segments Covered |

|

|

Regional Scope |

|

|

Competitive Landscape |

|

|

Report Format |

|

|

Customization |

Report customization as per your requirements with respect to countries, regions, and segmentation. |

FAQ's

The global market size was valued at USD 2.64 billion in 2024 and is projected to grow to USD 4.76 billion by 2034.

The global market is projected to register a CAGR of 6.1% during the forecast period.

Asia Pacific dominated the market share in 2024.

A few of the key players in the market are CPC Machines; LPM Group; Hashida Giken Inc.; ISUZU MFG; SINTOKOGIO, LTD.; Colosio Srl; WELTOP MACHINERY; Buhler AG; Toshiba Machine Co., Ltd.; Idra Group; UBE Industries, Ltd.; Dynacast International; and Zhejiang Wanfeng Technology Development Co., Ltd.

The automatic segment dominated the market share in 2024.

The vertical segment is expected to witness the significant growth during the forecast period.